Supply OEM/ODM Metal Roofing Coil - Stud and Track roll forming machine – Linbay Machinery Detail:

Description:

The Stud and Track Roll Forming Machine, as known as Hat Shape Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine Light Steel Keel Roll Forming Machine etc. can produce studs, tracks and many other shapes derived form Shape C.

The thickness is normally can be formed at 0.25-1.2mm .

If you need to more efficiency then we recommend you adpot the Flying shear with No-stop system .

The Max. whole line speed can be reach at 40m/min.

If you want to produce more than one profile in one machine, we recomend you the double rows forming machine and triple rows forming machine to save space and economy.

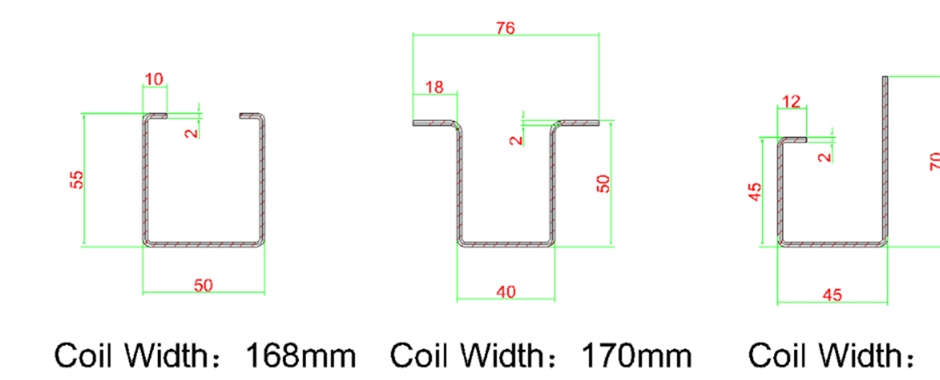

Profile:

Technical specification:

|

Stud, Track and Channel Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.25-1.2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-40 | Or according to your requirement |

|

3 |

Forming station |

8-14 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

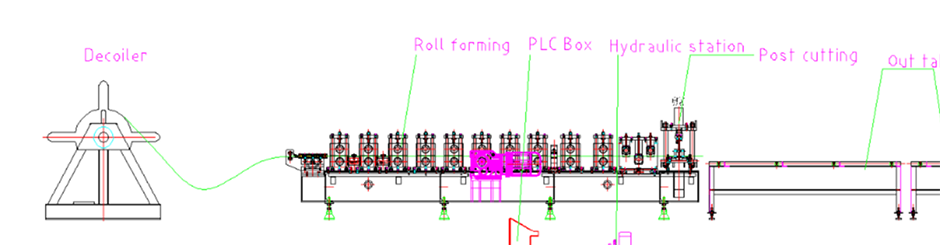

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for Supply OEM/ODM Metal Roofing Coil - Stud and Track roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Cancun, Panama, Nairobi, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Send your message to us:

-

Factory Customized Sheet Roof Roll Forming Mach...

-

Manufacturer for Sheet Metal Tile Forming Machi...

-

Factory Price For Light Gauge Steel Framing Mac...

-

China Factory for Galvanized Decking Sheet Mach...

-

Trending Products Used Metal Roll Forming Machi...

-

factory low price Light Keel Roll Forming Machi...