Top Grade Downspouts Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

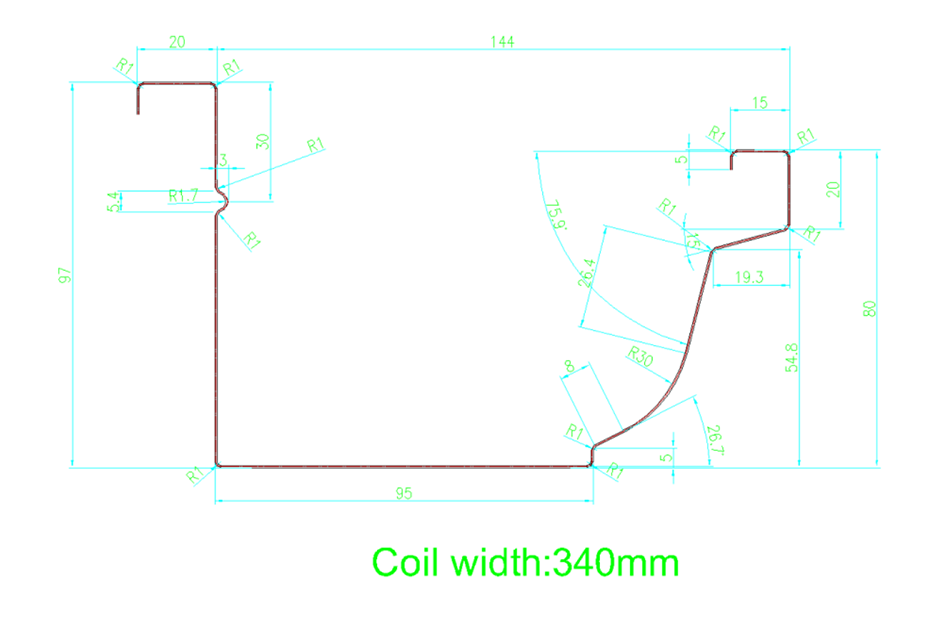

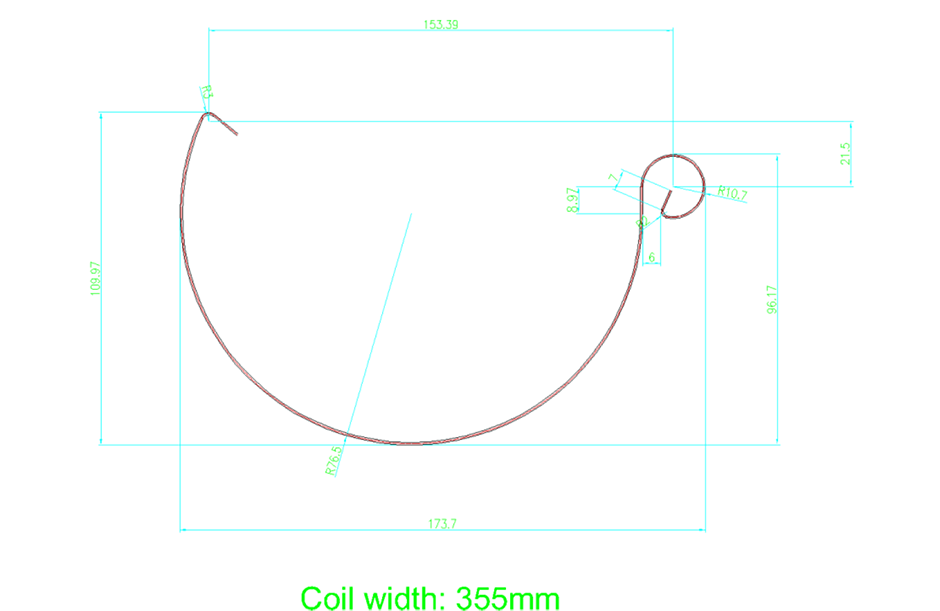

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

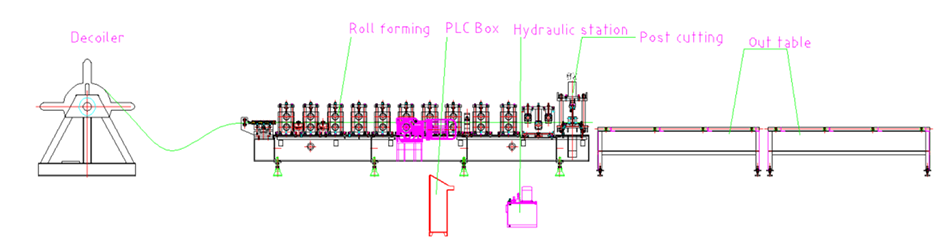

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Understanding Roll Forming Machines

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Top Grade Downspouts Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Ukraine, Chile, Turkey, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

Send your message to us:

Write your message here and send it to us

-

Factory directly Double Type Light Keel - Ridg...

-

Professional China Z Steel Profile - Strut and...

-

Manufacturer for Purlin Roll Forming Machine -...

-

Hot-selling Metal Deck Scaffolding Roll Forming...

-

Wholesale Discount Corrugated Roof Panel Machin...

-

Big Discount Frp Roof Sheet Roll Forming Machin...