Top Quality Roof Double Layer Roll Forming Machine - PU Sandwich Panel Production Line – Linbay Machinery Detail:

Description:

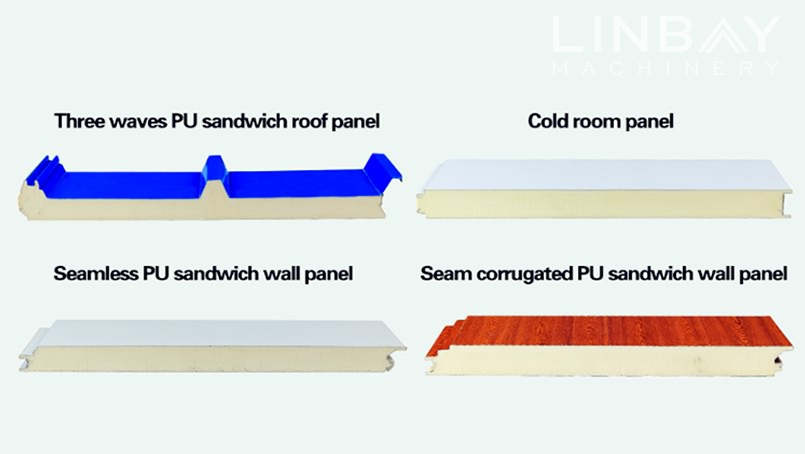

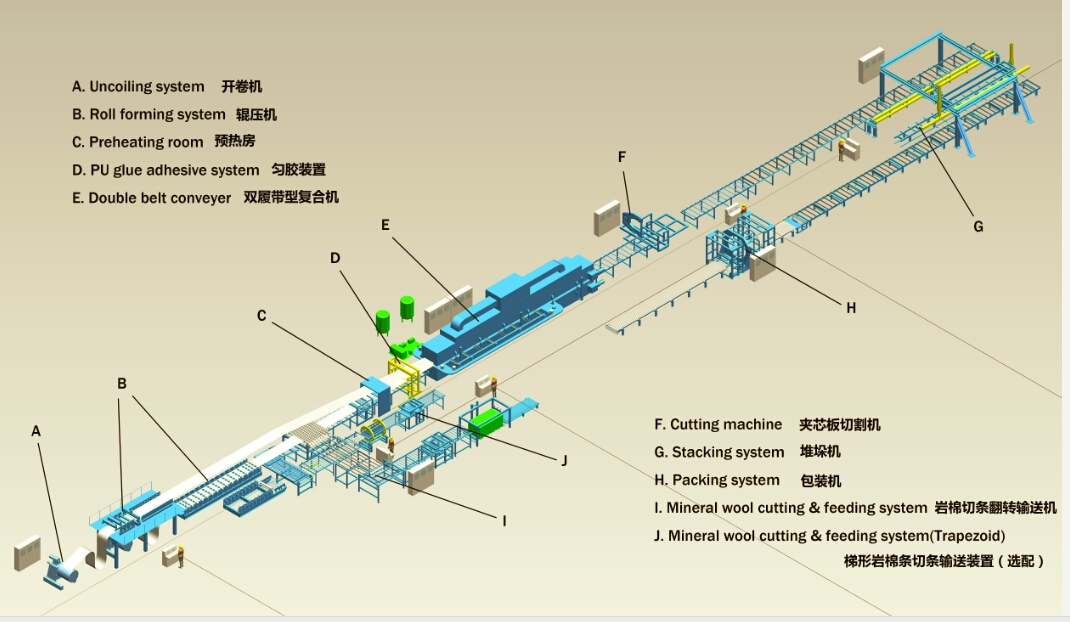

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Guide On How To Use a Roll Forming Machine

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our enterprise with the long-term to build with each other with consumers for mutual reciprocity and mutual advantage for Top Quality Roof Double Layer Roll Forming Machine - PU Sandwich Panel Production Line – Linbay Machinery, The product will supply to all over the world, such as: Barcelona, Anguilla, Honduras, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Send your message to us:

-

Chinese wholesale Shelf Panel Roll Forming Mach...

-

New Fashion Design for Cold Rolled Line - Down...

-

Factory Price Used Metal Roll Forming Machine -...

-

Factory Price Colored Metal Steel Panel Roll Fo...

-

2018 Latest Design Zlp800 Aluminum Suspended Wo...

-

Low price for High-Rise Roof Suspended Work Pla...