Trending Products Wall Angle Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery Detail:

Description:

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

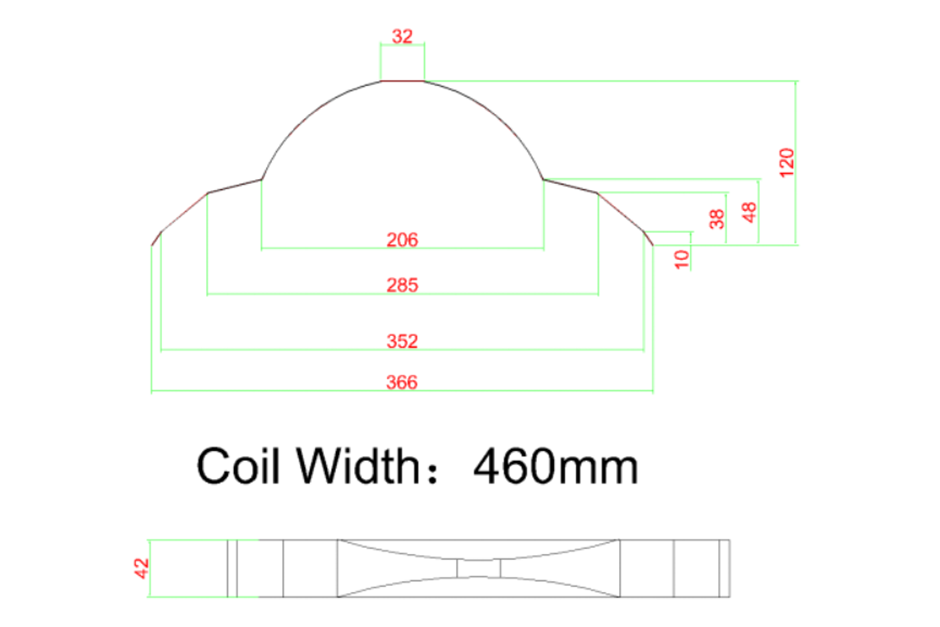

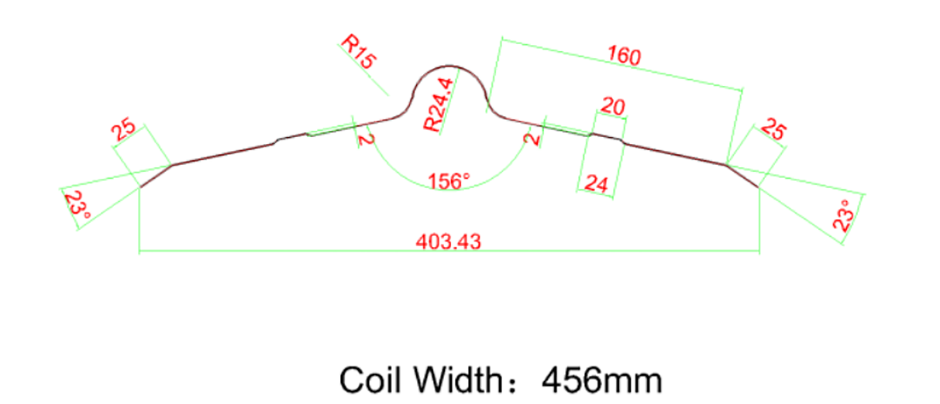

Profile:

Technical specification:

|

Ridge cap roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

14 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

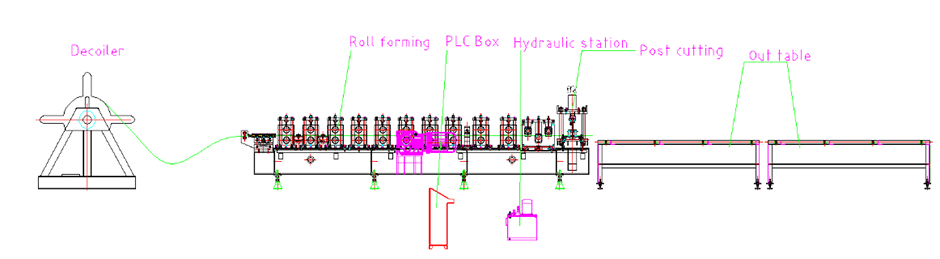

Flow Chart:

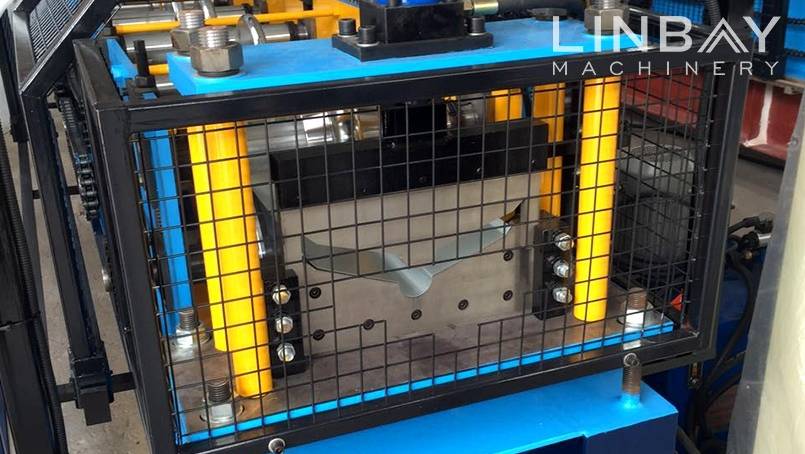

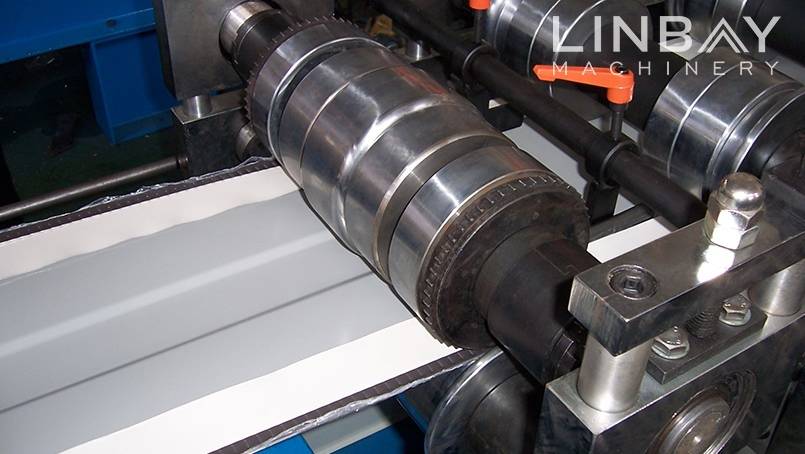

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for Trending Products Wall Angle Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Jeddah, Turkey, Spain, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Send your message to us:

-

Hot-selling 240 Roll Forming Machine - Stud an...

-

Hot Sale for Rolling Mill Line - Downspout Pip...

-

Quoted price for Double Layer Tile Making Machi...

-

ODM Factory Roofing Tile Roll Forming Machine -...

-

Supply OEM Aluminum Composite Panel Cutting Mac...

-

Wholesale Discount Metal Panel Roll Forming Equ...