Well-designed Wall Panel Roll Forming Line - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

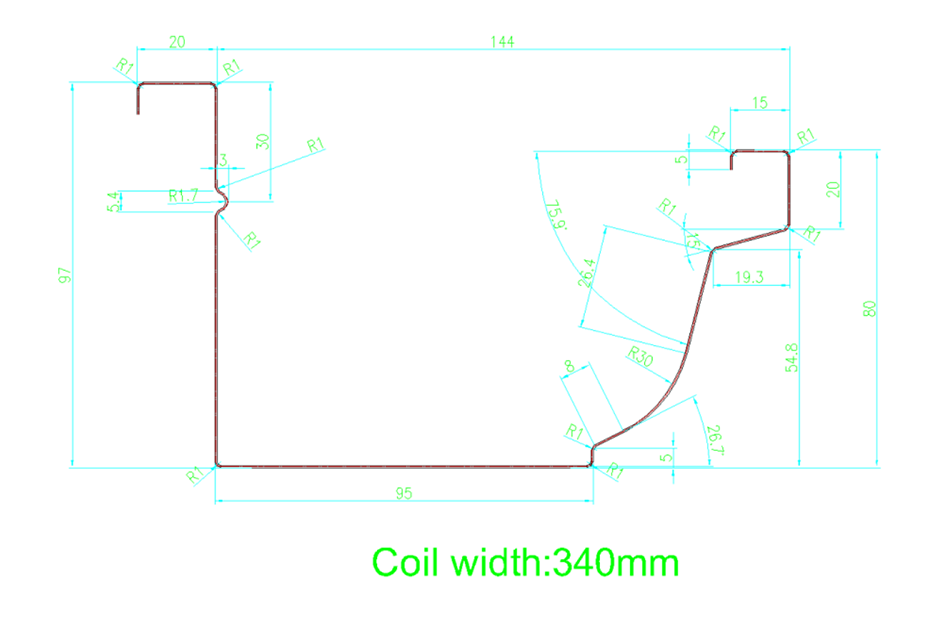

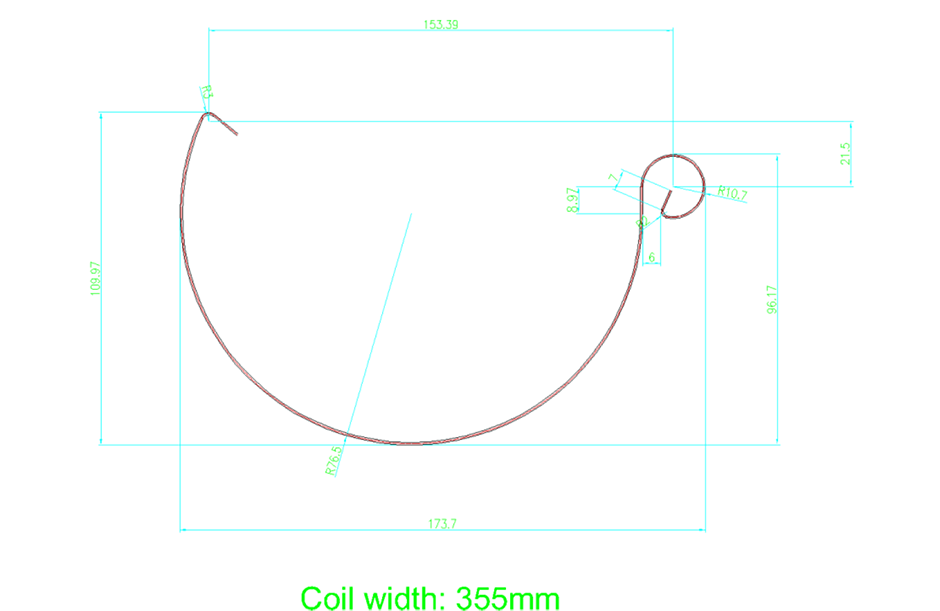

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

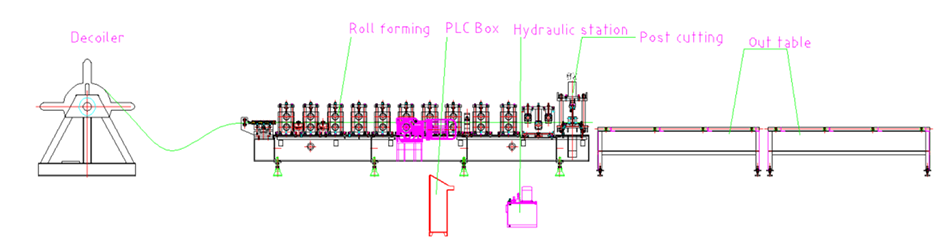

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Well-designed Wall Panel Roll Forming Line - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Argentina, Slovakia, Cairo, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

Send your message to us:

Write your message here and send it to us

-

Discountable price Light Weight Roll Forming Ma...

-

Personlized Products Steel Tile Roll Forming Ma...

-

Factory Free sample High Quality Metal Sheet Ro...

-

2018 Latest Design Zlp800 Aluminum Suspended Wo...

-

IOS Certificate Roofing Machine - Strut and Ra...

-

Factory Customized Sheet Roof Roll Forming Mach...