Wholesale Price Galvanized Aluminum Sheet Roll Forming Machine - Double Layer Panel roll forming machine – Linbay Machinery Detail:

Description:

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

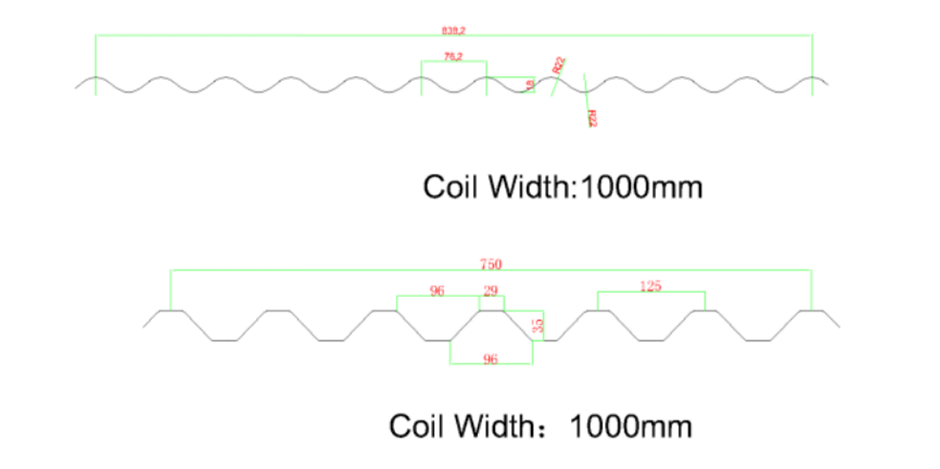

Profile:

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

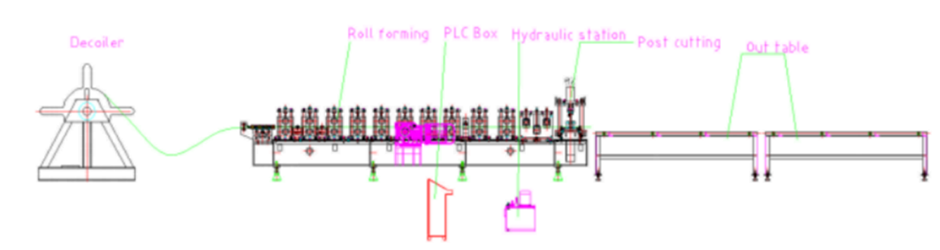

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

We insist on offering high quality production with good business concept, honest sales and the best and fast service. it will bring you not only the high quality product and huge profit, but the most significant is to occupy the endless market for Wholesale Price Galvanized Aluminum Sheet Roll Forming Machine - Double Layer Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Belgium, Malta, Portland, With the technology as the core, develop and produce high-quality products according to the diverse needs of the market. With this concept,the company will continue to develop products with high added values and continuously improve products,and will provide many customers with the best products and services!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

Send your message to us:

-

OEM/ODM Factory Steel Door Frame Roll Forming M...

-

China New Product Making Machine With C - Step...

-

Manufacturing Companies for Ld Formed Rolling F...

-

8 Years Exporter Best Price Roll Forming Machin...

-

8 Years Exporter Best Price Roll Forming Machin...

-

Competitive Price for Color Glazed Tile Roll Fo...