Wholesale Trapezoidal Roof Tile Making Machine Price - Z Purlin roll forming machine – Linbay Machinery Detail:

Description:

Z Purlin Roll Forming Machine can produce from 100-400mm purlin width . Normally the thickness can be formed at 1.5-3.0 mm. The lips angles can be at 45 or 90 degrees.Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal or chain drving according to your requirement.We can design the machine as Torri Stand structure or Metal wall structure.

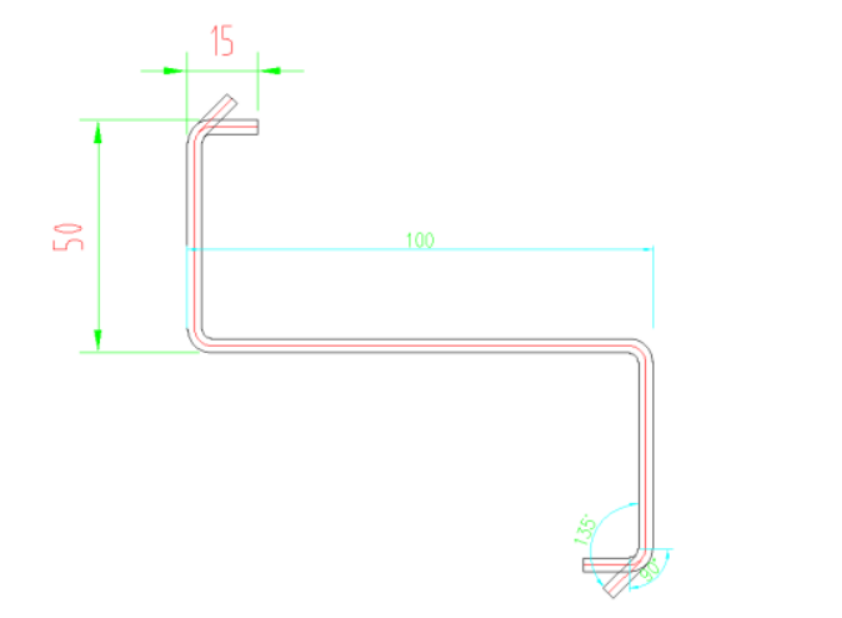

Profile:

Technical specification:

|

Z Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

|

3 |

Forming station | 18 | According to your profile |

|

4 |

Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor | Sino-German Brand | Siemens |

|

6 |

PLC brand | Panasonic | Siemens |

|

7 |

Inverter brand | Yaskawa | |

|

8 |

Driving system | Chain drive | Gearbox drive |

|

9 |

Rollers’ materail | Steel #45 | GCr15 |

|

10 |

Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system | No | Hydraulic punching station or Punching press |

|

12 |

Cutting system | Post-cutting | Pre-cutting |

|

13 |

Power supply requirement | 380V 60Hz | Or according to your requirement |

|

14 |

Machine color | Industrial blue | Or according to your requirement |

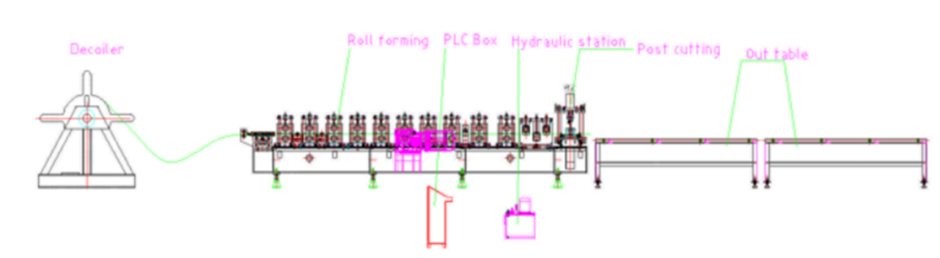

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Wholesale Trapezoidal Roof Tile Making Machine Price - Z Purlin roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Lithuania, Peru, Auckland, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Send your message to us:

Write your message here and send it to us

-

Reliable Supplier Roll Forming Machine Manufact...

-

PriceList for Cold Wall Panel Roll Forming Mach...

-

Best quality Hydraulic Metal Roll Forming Machi...

-

Super Lowest Price Powered Suspended Platform -...

-

Cheap price Drywall Roll Forming Machines - Su...

-

OEM/ODM Supplier Steel Roof Forming Machine - ...