Best Price on Double Layer Roofing/Wall Panel Roll Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

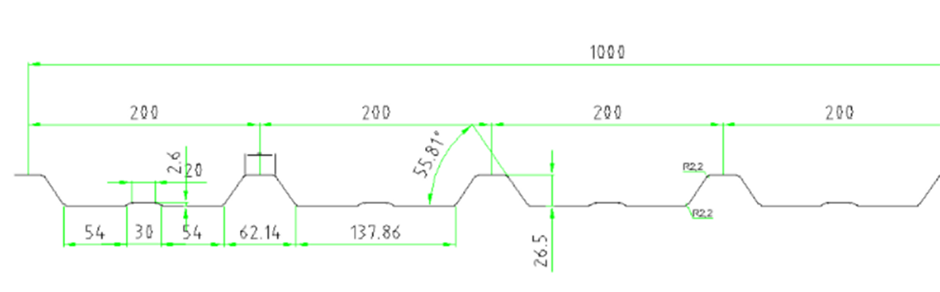

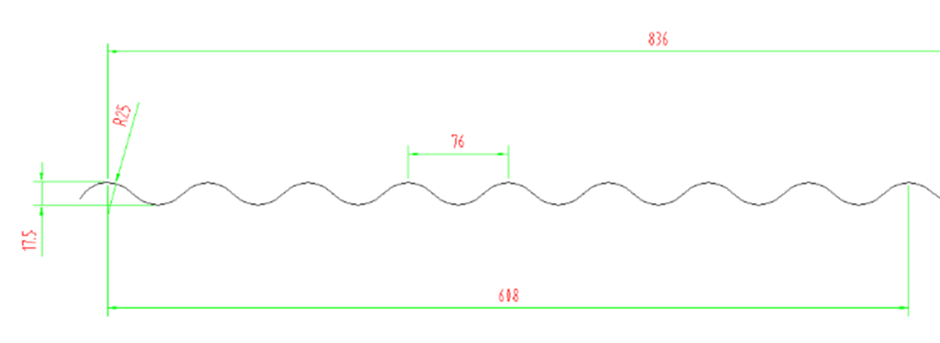

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

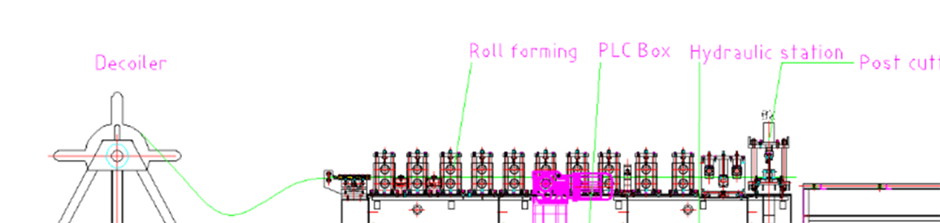

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for Best Price on Double Layer Roofing/Wall Panel Roll Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Moscow, Mongolia, Lisbon, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Send your message to us:

-

Factory source Light Keel Steel Frame Forming M...

-

China Gold Supplier for Cable Tray Forming Mach...

-

Wholesale Dealers of Double Layer Color Steel T...

-

Well-designed Decking Sheet Machine - Step Bea...

-

OEM/ODM China Gutter Roll Forming Machine - Do...

-

factory low price U Channel Roller Shutter Roll...