The key to our success is “Good Products Good quality, Reasonable Price and Efficient Service” for Big discounting China Ladder Type Cable Tray Roll Forming Machine, You would not have any communication problem with us. We sincerely welcome clients all over the world to get hold of us for organization cooperation.

The key to our success is “Good Products Good quality, Reasonable Price and Efficient Service” for Cable ladder system, Cable Tray Roll Forming Machine, China Roll Forming Machine, Extra heavy duty cable ladder, Heavy duty cable ladder, Hot dip galvanized Steel cable ladder, Medium duty cable ladder, MS & GI Ladder Cable Trays for Industria, slotted rail cable ladder, Stainless Steel Ladder Cable Trays, Steel Cable Ladders, Steel Hot Dip Galvanized Ladder Type Cable Trays, Swifts Medium Duty Cable Ladder, Ventilated trays, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we’ve got gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Description

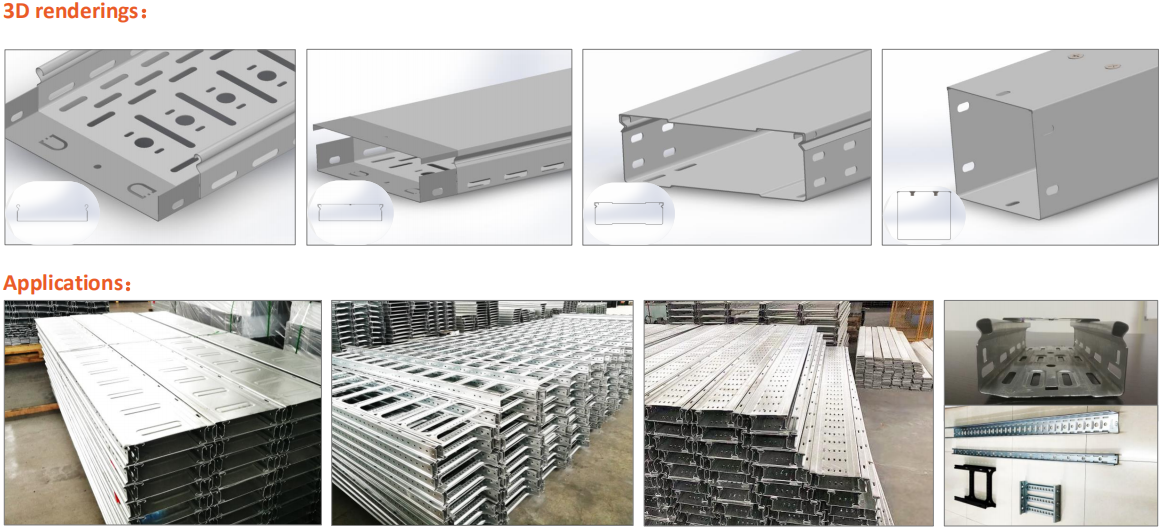

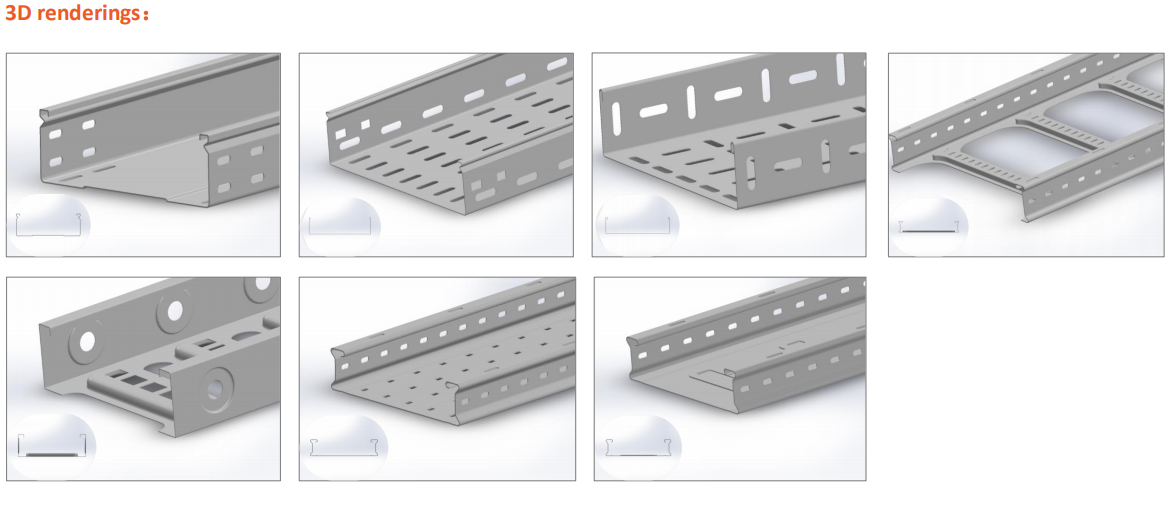

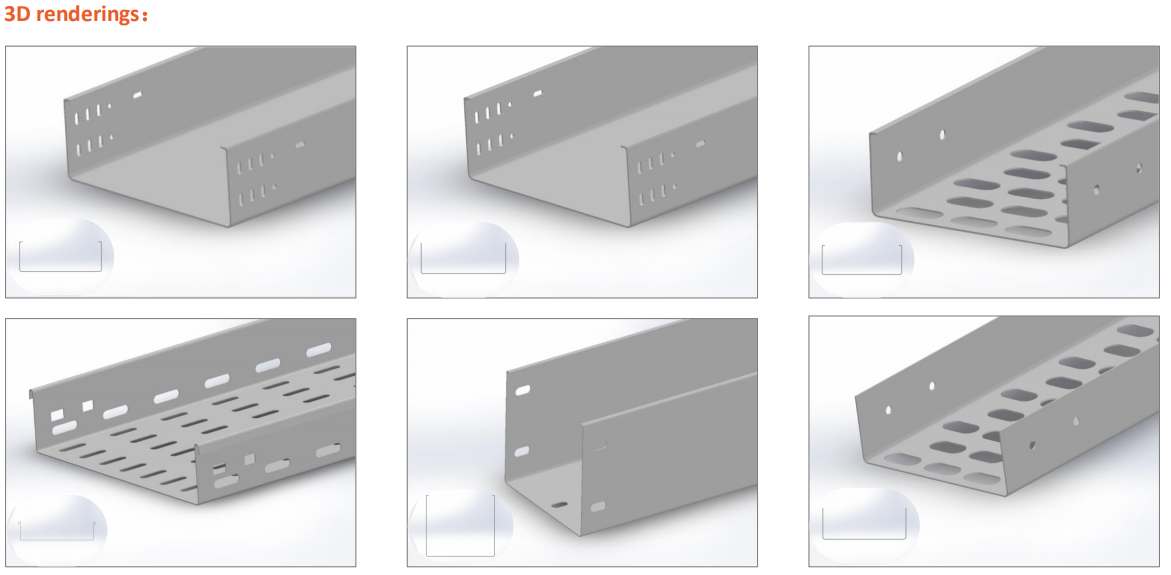

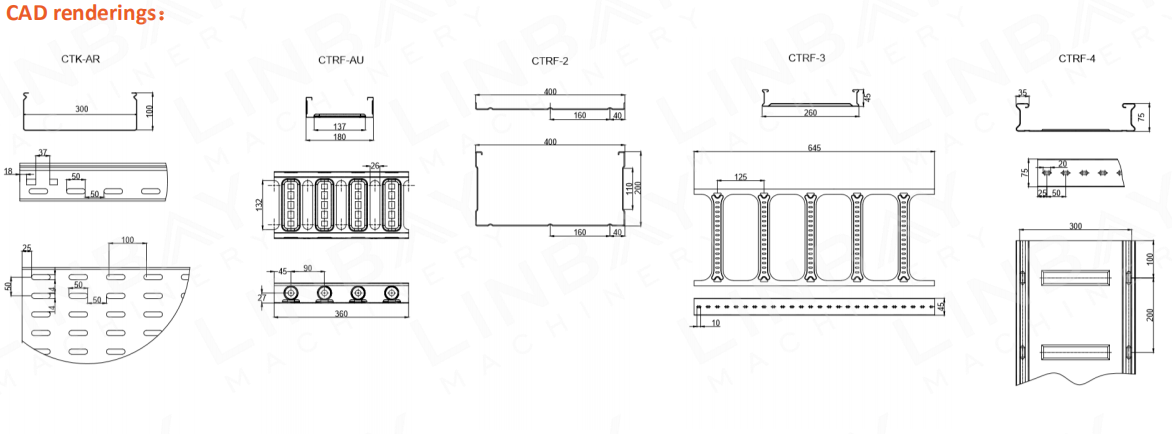

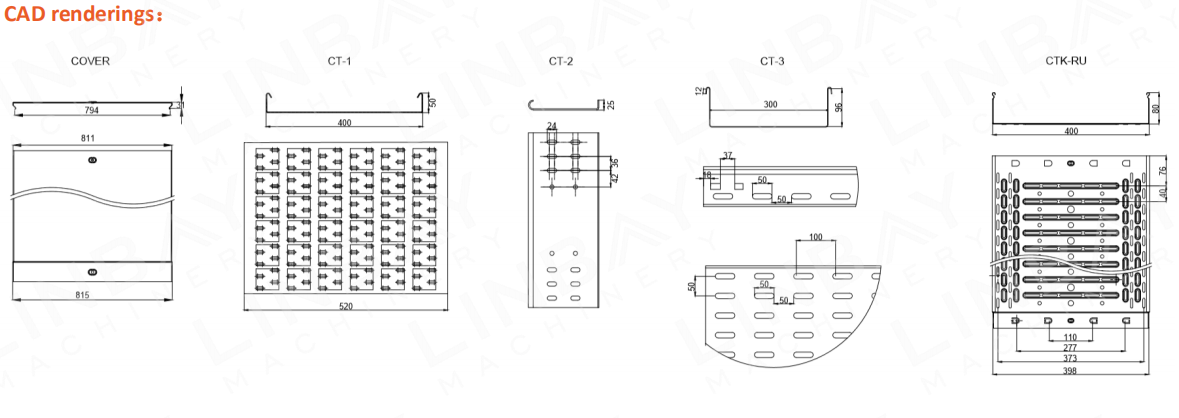

Cable ladder roll forming machine is commonly used for cable management in commercial and industrial construction. This intelligent roll former could produce different types of cable trays like: Solid bottom cable tray, Trough cable tray, Channel cable tray, Perforated cable tray, Non perforated cable tray and Trunking cable tray etc. with different raw materials like: hot-dip galvanized steel, pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2mm. You could set up 10 different lengths for cable tray.

In Electrical Industries, we are able to manufacture more machines like strut channel roll forming machine, DIN rail roll forming machine and Electrical Enclosure Box roll forming machine etc.

Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

Real Case A

Description:

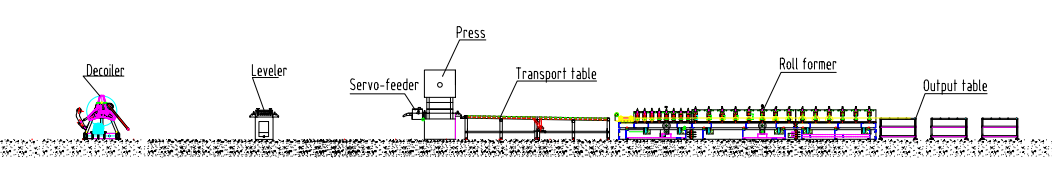

This Cable Tray Line is a new innovation in 2019, using a pre-cut system, cutting blades are embedded into punch mould, so it achieves punch and cut together in punch press. This idea makes working speed faster and save cutting device for our customer.

Real Case B

Description:

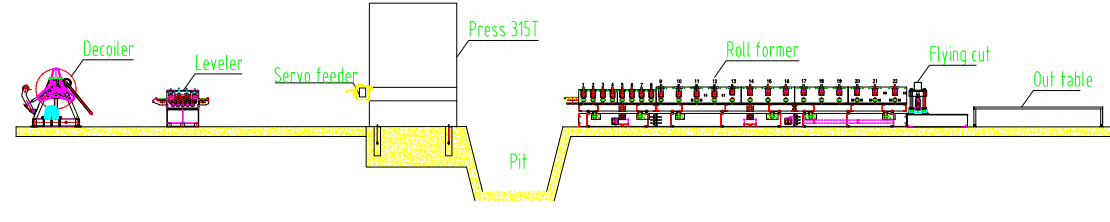

This cable tray production line achieves two types of change in one machine. You could change from cable tray to tray cover (profile to profile) and set up different sizes of cable tray or tray cover from 50 to 600mm(width) from 35 to 100mm(height). This intelligent roll former saves money, space and time for our customer.

Whole production line of Cable ladder roll forming machine

Technical Specifications

|

Automatic Cable Tray Roll Forming Machine |

||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.6-1.2, 1-2 |

| B) PPGI | ||

| C) Carbon steel | ||

| Yield strength : | 250 – 550 Mpa | |

| Tensil stress : | G250 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | According to your profile drawings | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Cantilever type | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

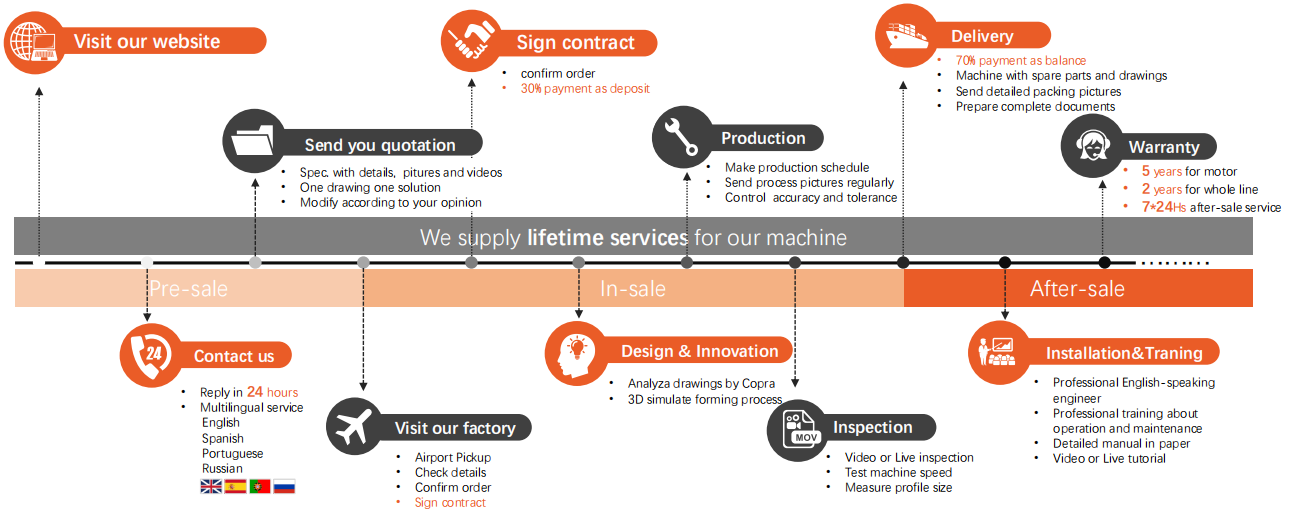

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing cable tray roll forming machine?

A: We have exported cable tray production line to Russia, Australia, Argentina, Malaysia, Indonesia. We have produced perforated cable tray, CT cable tray, ladder cable tray and etc. We are confident to solve your cable tray problem.

2. Q: Can I just use one line to produce cable tray and tray cover?

A: Yes, you definitely can use one line to produce cable tray and tray cover. The change operation is simple, you can complete it in half an hour. In this way, this will greatly reduce your cost and time.

3. Q: What is delivery time of cable tray machine?

A: 120 days to 150 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. Please send us your drawing and let us know your required speed, we would customize it for you.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Cheap price China C&U 90-305mm Light Steel...

-

Top Grade China Full Automatic C/Z Purlin Roll ...

-

Cheap PriceList for China Roof Tile and Wall Pa...

-

Lowest Price for China Jm85 Roll Forming Machin...

-

OEM Factory for China Colorful Cement Roof Tile...

-

OEM/ODM Manufacturer China Supermarket Shelf St...