Bottom price Corrugated Steel Roofing Sheet Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

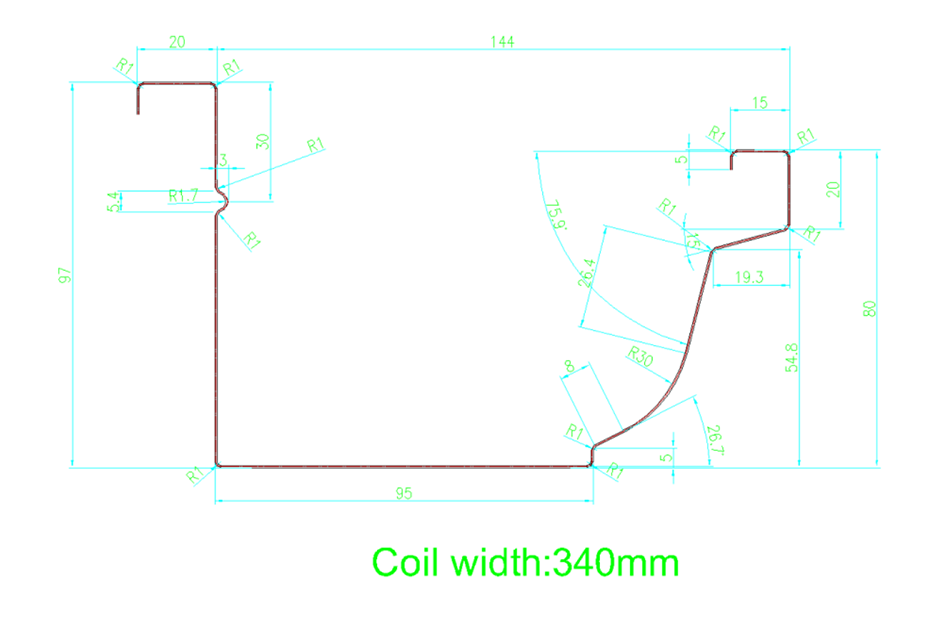

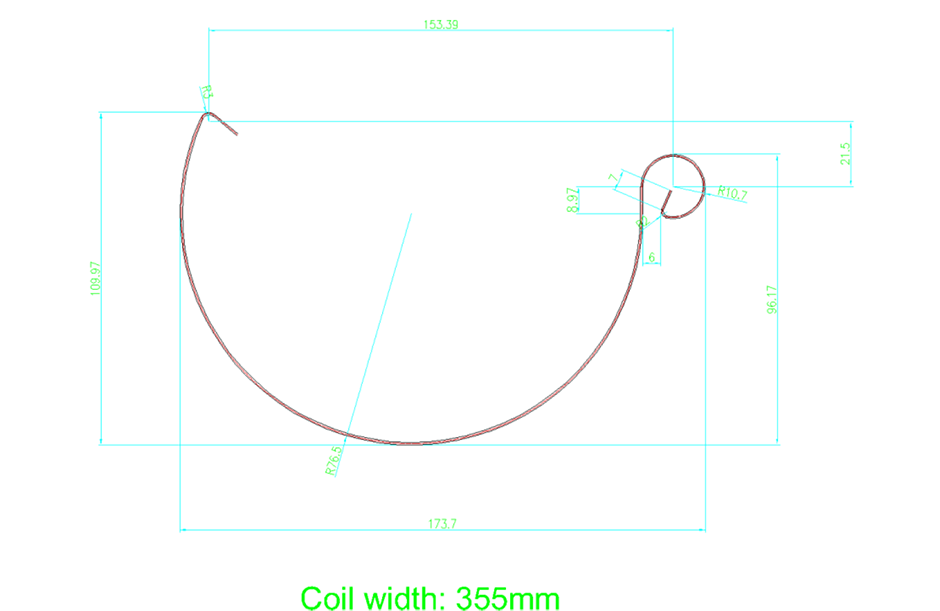

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

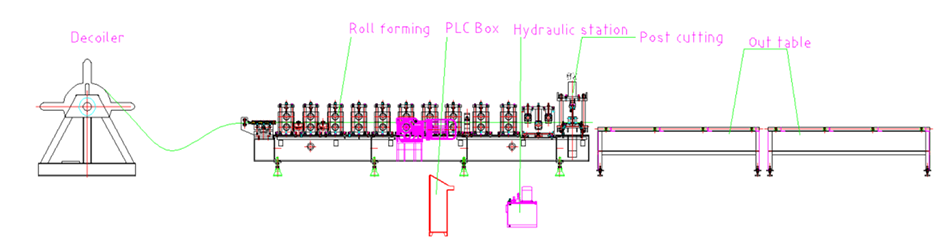

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Cold Roll Forming Machines – New Army in Steel Construction Industry

No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Bottom price Corrugated Steel Roofing Sheet Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Munich, Thailand, Namibia, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

Send your message to us:

Write your message here and send it to us

-

8 Years Exporter Scaffolding Roll Forming Machi...

-

Big discounting Metal Badge Making Machine - D...

-

Manufacturing Companies for Curved Door Frame R...

-

Top Quality Foam Roller Shutter Door Line - Do...

-

Manufacturer for Purlin Roll Forming Machine -...

-

High Quality Floor Deck Roll Forming Machine Pr...