Factory Cheap Hot Roofing Arch Sheet Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery Detail:

Description:

Steel Strut&Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Steel C Channel Roll Forming Machine, Solar Rack Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min. We adopt gearbox driving system to keep our machine work with high speed and prolong the service life.

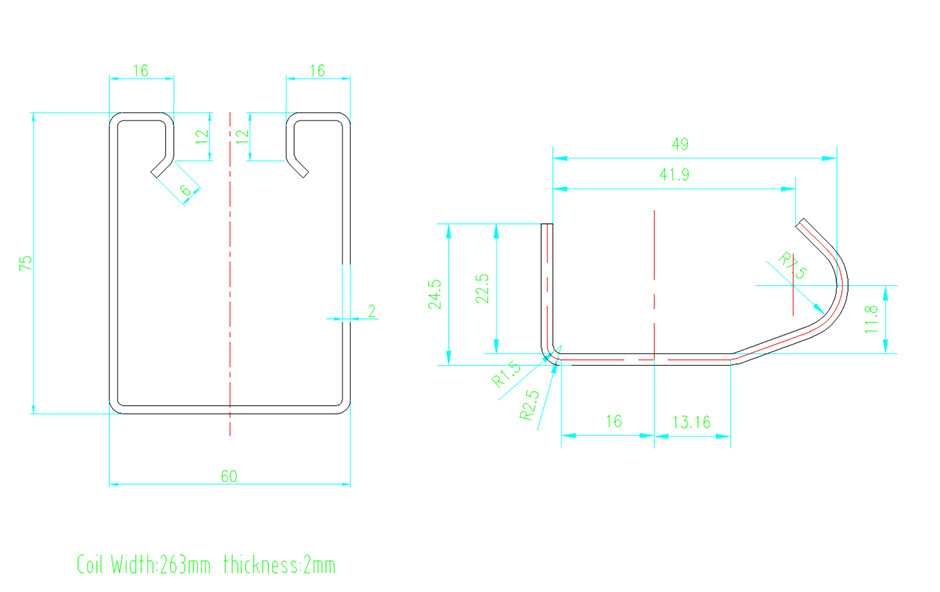

Profile:

Technical specification:

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

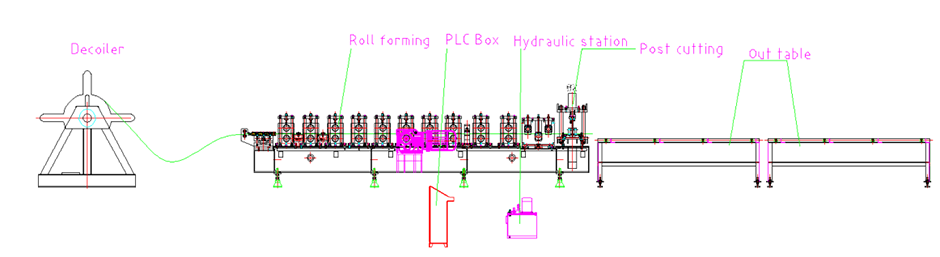

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

We are proud of the superior customer gratification and wide acceptance due to our persistent pursuit of top of the range both of those on merchandise and service for Factory Cheap Hot Roofing Arch Sheet Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Argentina, Congo, Estonia, All the imported machines effectively control and guarantee the machining precision for the products. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality products and have the ability to develop new products to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Send your message to us:

-

OEM/ODM China Building Material Machinery - Ca...

-

Hot sale Factory Corrugated Metal Roll Forming ...

-

Manufactur standard Customized Working Platform...

-

factory low price Metal Roof Sheet Machine - S...

-

2018 wholesale price Tile Making Machinery - D...

-

Cheapest Factory Roller Shutter Door Roll Formi...