Factory Customized Sheet Roof Roll Forming Machine - Highway Guardrail roll forming machine – Linbay Machinery Detail:

Description:

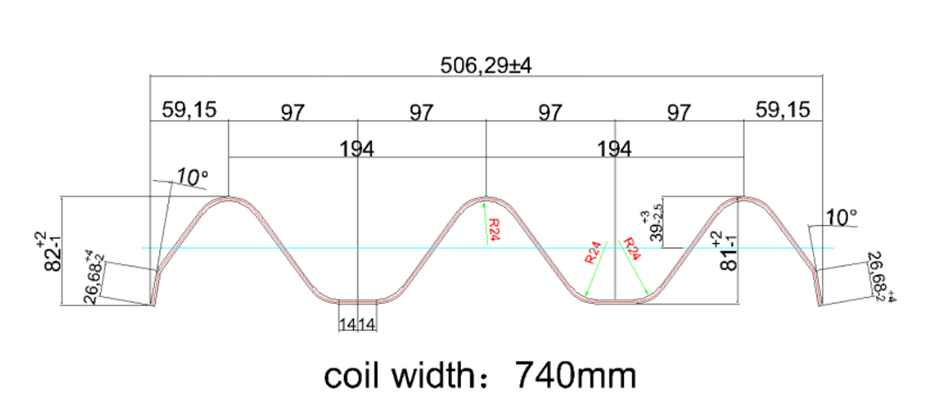

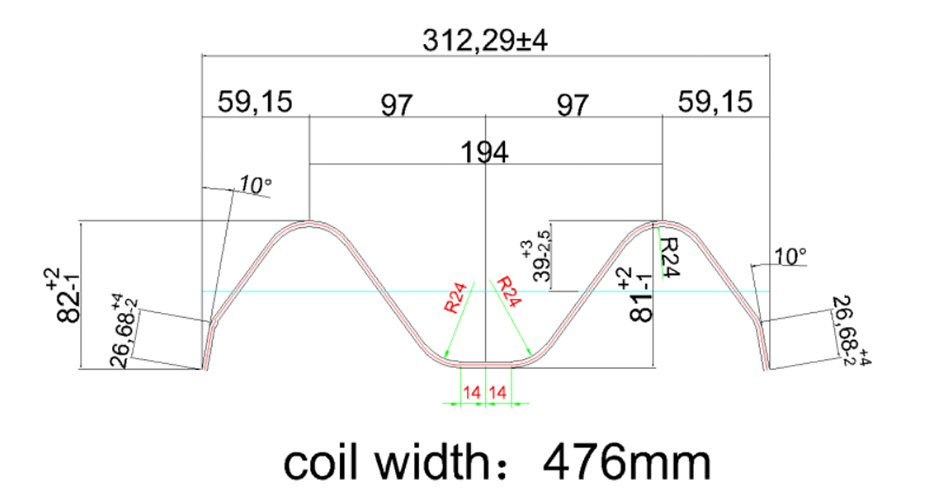

This Highway Guardrail Roll Forming Machine can be designed as two waves or three waves profiles in one machine just need to add some stations at the end of the machine. We adopt the universal joint driving system. The Max.thickness can reach at 4.0mm.

Profile:

Technical specification:

|

Two Waves/Three Waves Highway Guardrail Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):2-4 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

15 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Cr12 | GCr15 or #45 Steel |

|

10 |

Station structure |

Forged Iron station | Wall panel station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

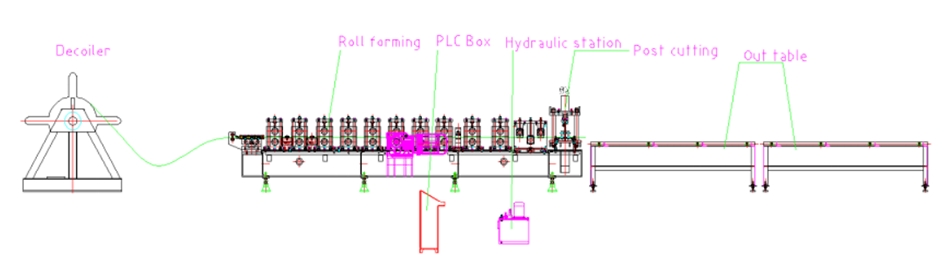

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Guide On How To Use a Roll Forming Machine

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Factory Customized Sheet Roof Roll Forming Machine - Highway Guardrail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Washington, United States, Mecca, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Send your message to us:

-

Factory made hot-sale High Quality Roller Shutt...

-

New Fashion Design for Cold Rolled Line - C Z ...

-

New Arrival China Ibr Metal Sheet Forming Line ...

-

China Manufacturer for Galvanized Metal Studs A...

-

Wholesale Discount Metal Panel Roll Forming Equ...

-

Price Sheet for High Precision Roll Forming Mac...