Factory made hot-sale Standing Seam Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

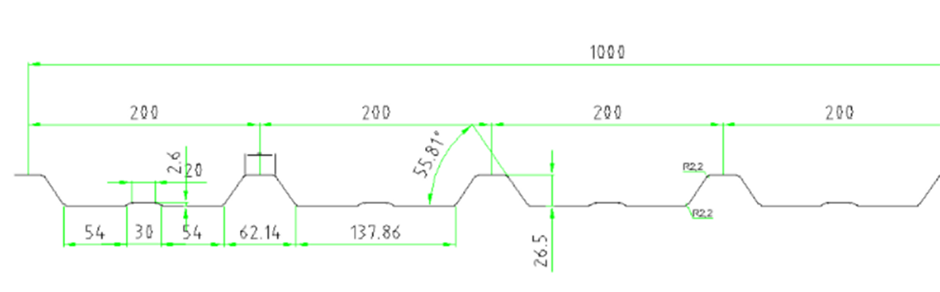

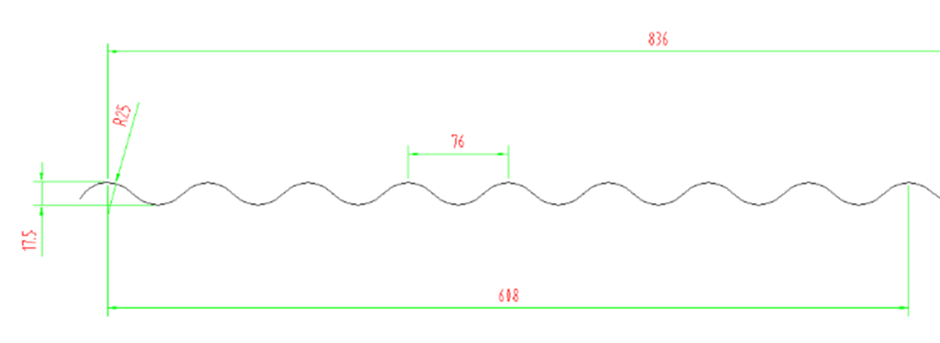

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

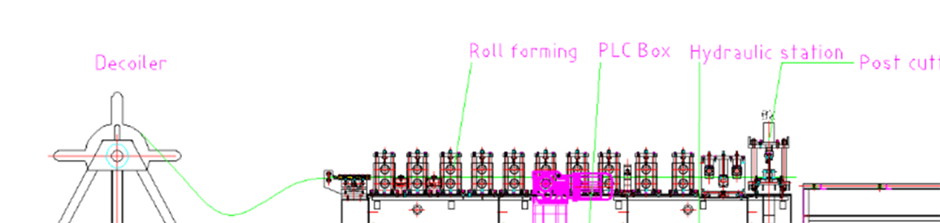

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Cold Roll Forming Machines – New Army in Steel Construction Industry

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for Factory made hot-sale Standing Seam Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Kuala Lumpur, Ireland, Philadelphia, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have now the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

Send your message to us:

-

2018 New Style Roofing Sheet Roll Forming Machi...

-

OEM Factory for Platform Customized Work Platfo...

-

OEM/ODM Manufacturer Multi Point Suspended Plat...

-

Factory Cheap Aluminium Roofing Sheet Making Ma...

-

2018 New Style Decking Panels Roll Forming Mach...

-

China Factory for Galvanized Decking Sheet Mach...