Factory directly High Speed Steel Profile Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery Detail:

Description:

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

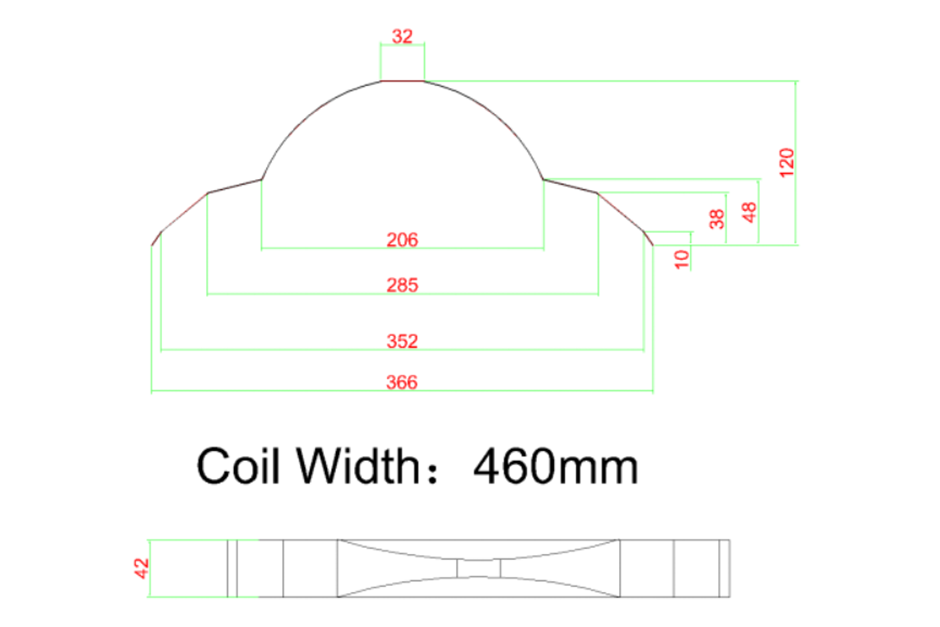

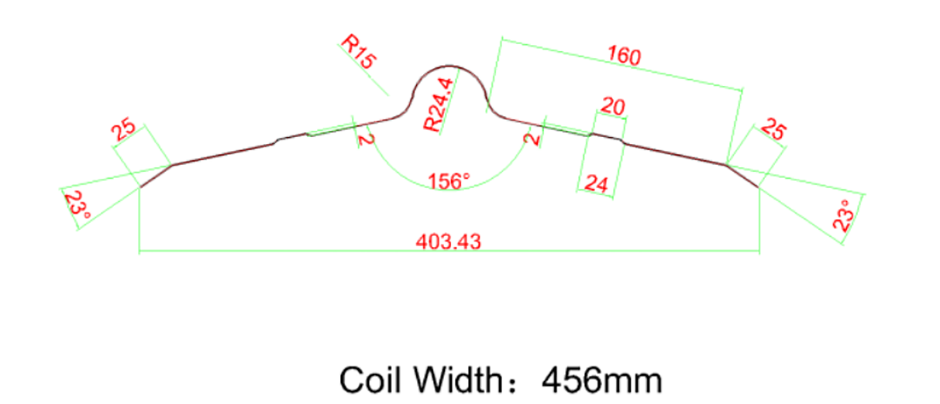

Profile:

Technical specification:

|

Ridge cap roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

14 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

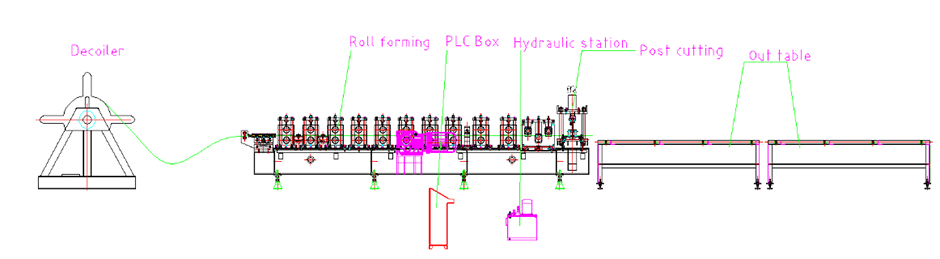

Flow Chart:

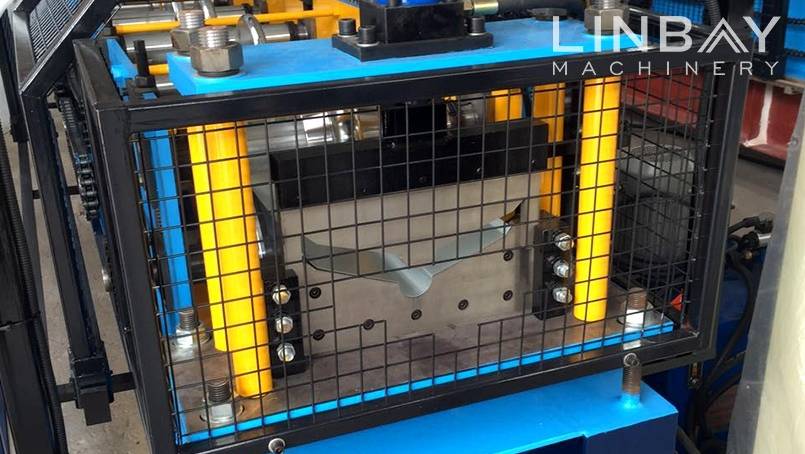

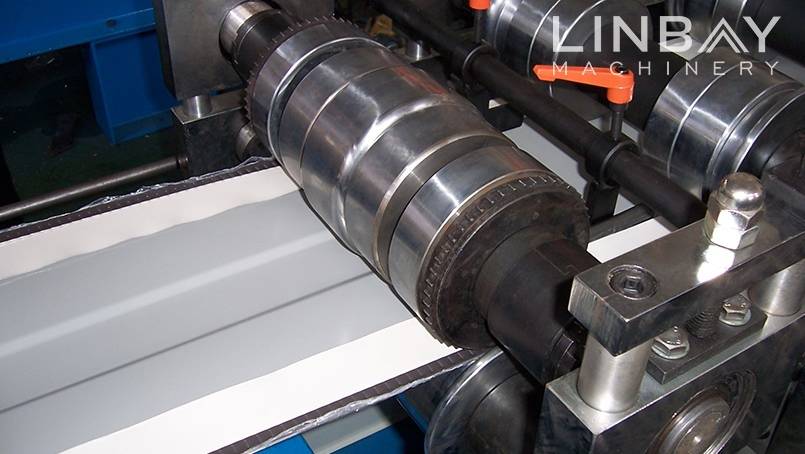

Product detail pictures:

Related Product Guide:

Cold Roll Forming Machines – New Army in Steel Construction Industry

Understanding Roll Forming Machines

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Factory directly High Speed Steel Profile Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: South Africa, Melbourne, Ecuador, With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Send your message to us:

-

Reliable Supplier C And Z Purlin Forming Machin...

-

Renewable Design for Glazed Tiles Roll Forming ...

-

Best-Selling Ceiling Making Machine With C - R...

-

Online Exporter Rainwater Gutter Roll Forming M...

-

China OEM Profile Roll Forming Machine - Stud ...

-

Popular Design for Racking Upright Cold Roll Fo...