Factory For Cable Tray Roll Former - Roofing Tile roll forming machine – Linbay Machinery Detail:

Description:

This Corrugated Tile/Roofing tile Roll Forming Machine produce more artistic and more popular corrugation sheets in many countries. It can be formed materail thickness as 0.3-0.8mm.

We have two types of cutting system, one is normal cut and other is 3D cut. From the pictures, you can see 3D cut maintains the profile shape more beautiful than normal horizontal cut. Besides all of the parts are controlled by PLC and automatically.

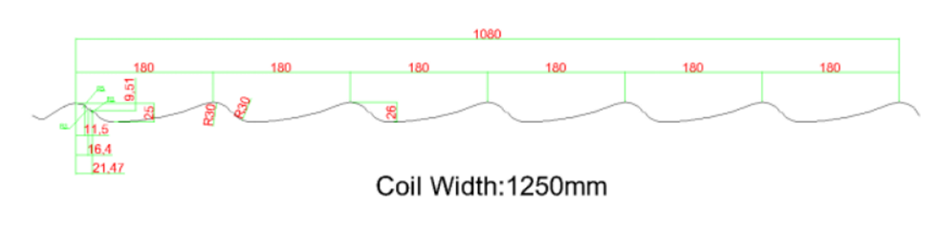

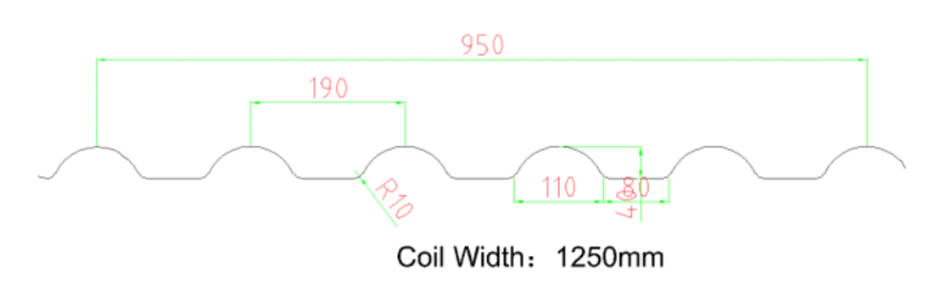

Profile:

Technical specification:

|

Corrugated Tile/Roofing tile Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

According to your profile | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

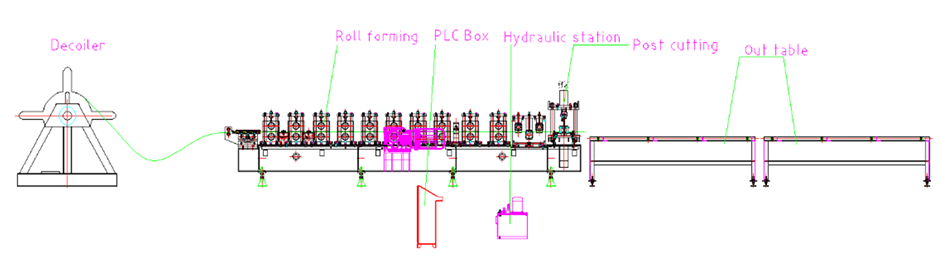

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Cold Roll Forming Machines – New Army in Steel Construction Industry

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme for Factory For Cable Tray Roll Former - Roofing Tile roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Germany, Swiss, Slovenia, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products and solutions, promote perfect services, cooperate for long-term and mutual benefits, firm a in depth mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

Send your message to us:

-

8 Years Exporter Cold Room Panel Roll Forming M...

-

Big discounting Roof Cold Roll Forming Machine ...

-

Discount wholesale Carriage Board Roll Forming ...

-

Professional China Ibr Metal Roofing Machine -...

-

Rapid Delivery for Ceiling Stud And Track Machi...

-

High Quality for Palisade Machine Fence - Step...