Manufacturer of Metal Truss And Track Machine - Double Layer Panel roll forming machine – Linbay Machinery Detail:

Description:

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

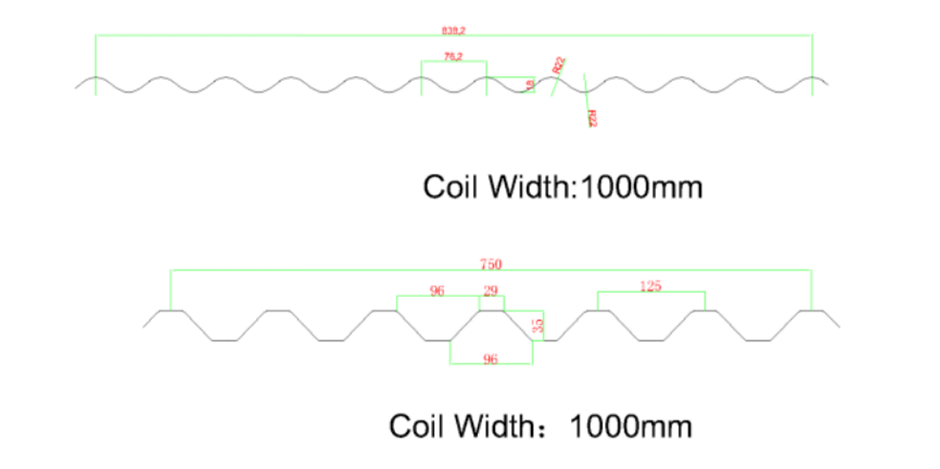

Profile:

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

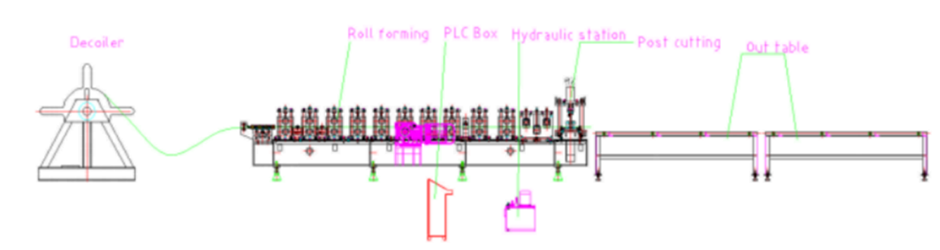

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Cold Roll Forming Machines – New Army in Steel Construction Industry

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Manufacturer of Metal Truss And Track Machine - Double Layer Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Czech Republic, Qatar, Serbia, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Send your message to us:

-

Big Discount C Shape Forming Machine - Rolling...

-

IOS Certificate Wall Cladding Roll Forming Mach...

-

Reasonable price for Downspouts Form Machine -...

-

High definition Metal Floor Deck Roll Forming M...

-

OEM/ODM Manufacturer Steel Tile Making Machine ...

-

Hot sale Factory C Channel Steel Roll Forming M...