Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for Massive Selection for China Tile Roof Panel Double Layer Roll Forming Machine, For more information, please contact us as soon as possible!

Our goal is usually to deliver high quality items at aggressive price ranges, and top-notch service to shoppers around the entire world. We’re ISO9001, CE, and GS certified and strictly adhere to their high quality specifications for China Roll Forming Machine, Cold Roll Forming Machine, double layer roof forming machine, downspout pipe roll forming machine, gutter roll former, K span, ridge cap production line, roof tile cold bending machine, Standing Seam Roll Forming Machine, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We are going to continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

Description

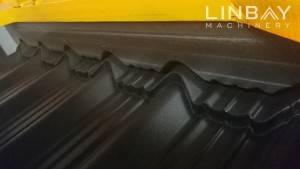

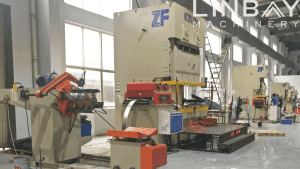

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Technical Specifications

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

Thickness(mm):0.3-0.8 |

|||

|

Yield strength: 250 – 550MPa |

|||

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|||

|

2 |

Nominal forming speed(m/min) |

10-25 |

Or according to your requirement |

|

3 |

Forming station |

20-23 |

According to your profile |

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Wall panel station |

Forged Iron station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

Flow Chart

Manual decoiler–feeding–roll forming–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Well-designed China Trapezoidal Roof Panel Stee...

-

Leading Manufacturer for China Slitting Metal S...

-

Professional China China C-Strut-C Channel Roll...

-

Popular Design for China Xiamen Liming Automati...

-

China Wholesale China C&Z Metal Interchang...

-

Big discounting High Speed Guardrail Roll Formi...