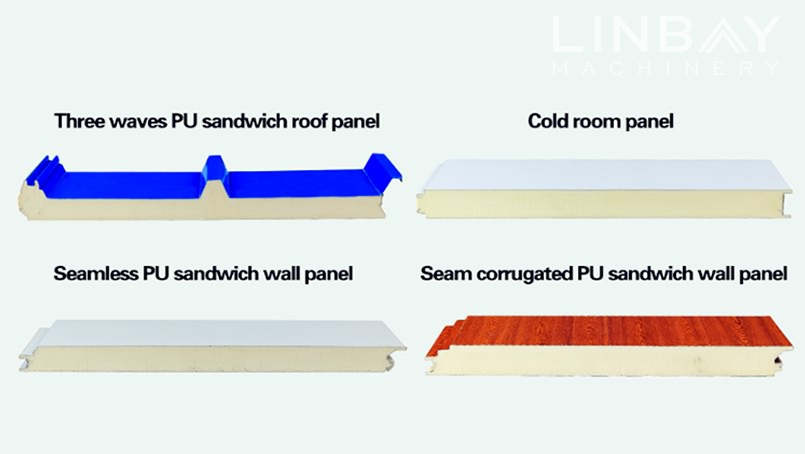

OEM China Wall And Roof Machine - PU Sandwich Panel Production Line – Linbay Machinery Detail:

Description:

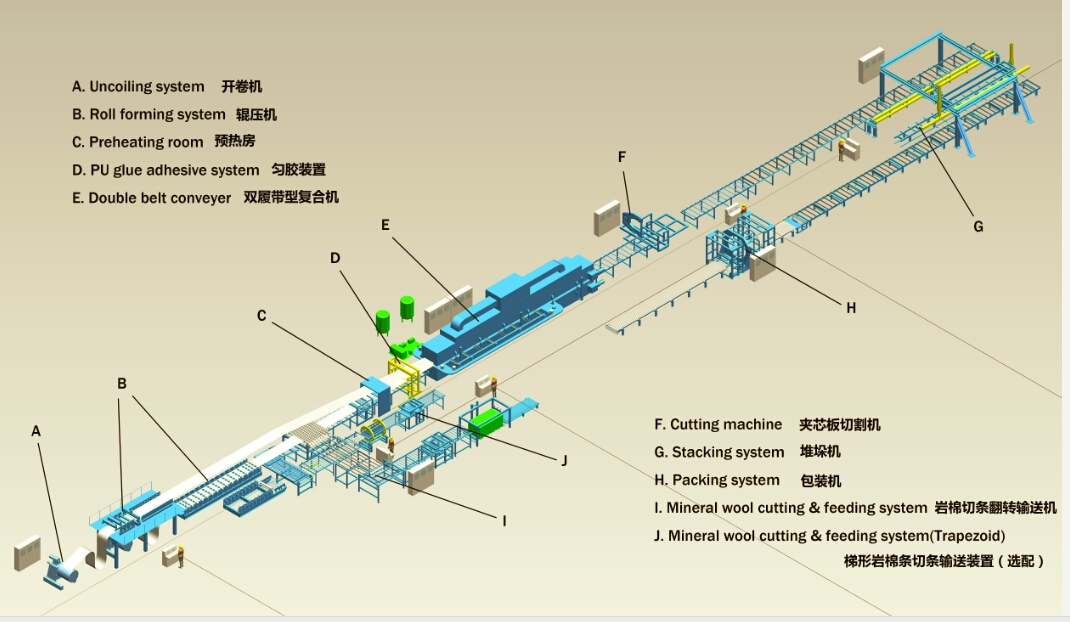

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for OEM China Wall And Roof Machine - PU Sandwich Panel Production Line – Linbay Machinery, The product will supply to all over the world, such as: Southampton, Hongkong, America, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Send your message to us:

-

Super Purchasing for Arch Roof Forming Machine ...

-

High definition Steel Molding Machine - Strut ...

-

2018 wholesale price C Channel Roll Forming Mac...

-

Special Design for Corrugated Sheet Roll Formin...

-

Professional Factory for Changeable C Purlin Ch...

-

Cheapest Factory Roller Shutter Door Roll Formi...