Original Factory Corrugated Steel Roofing Sheet Making Machine - Double Layer Panel roll forming machine – Linbay Machinery Detail:

Description:

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

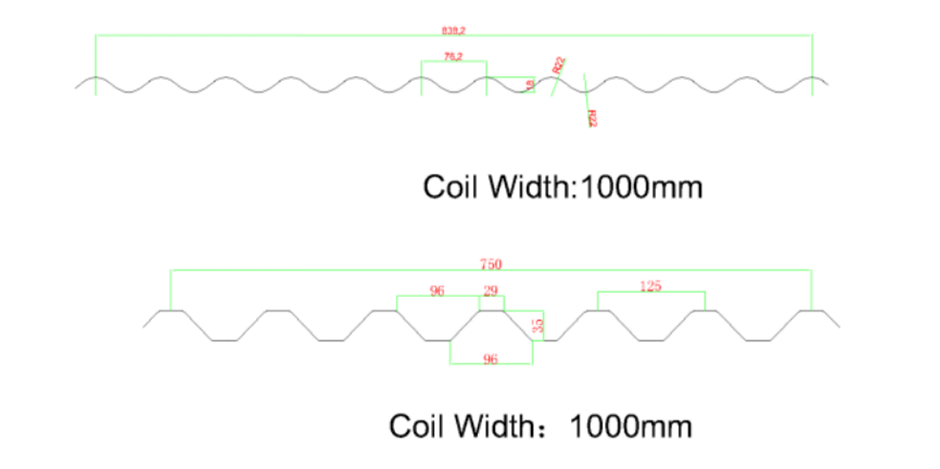

Profile:

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

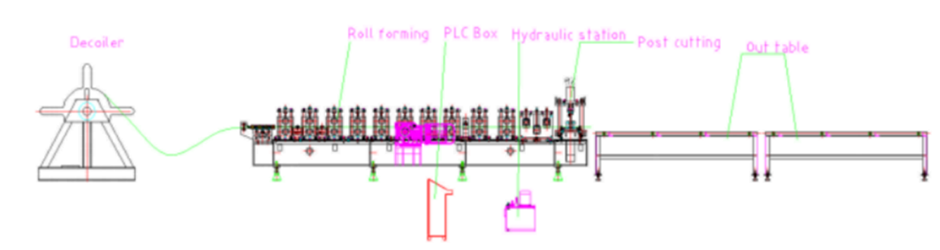

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Cold Roll Forming Machines – New Army in Steel Construction Industry

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Original Factory Corrugated Steel Roofing Sheet Making Machine - Double Layer Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Cambodia, Algeria, Lyon, Our products have enjoyed a great reputation for their good quality, competitive prices and prompt shipment in international market. Presently, we are sincerely looking forward to cooperating with more overseas customers based on mutual benefits.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

Send your message to us:

-

Reliable Supplier C And Z Purlin Forming Machin...

-

OEM/ODM Manufacturer Zinc Roofing Sheet Making ...

-

OEM/ODM Supplier Steel Roof Forming Machine - ...

-

Renewable Design for Used Roll Forming Machine ...

-

China Cheap price Used Portable Roof Roll Formi...

-

2018 wholesale price Solar Panels Roll Forming ...