Quots for Automatic High Speed Ridge Cap Tile Forming Machine - Shelf Rack roll forming machine – Linbay Machinery Detail:

Description:

Goods Shelf Roll Forming Machine including Shelf Roll Forming Machine, Pallet Rack Roll Forming Machine.Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Normally thickness can be formed at 2.5mm and the speed is about 20-30m/min.This machine is widely used in high warehouses.

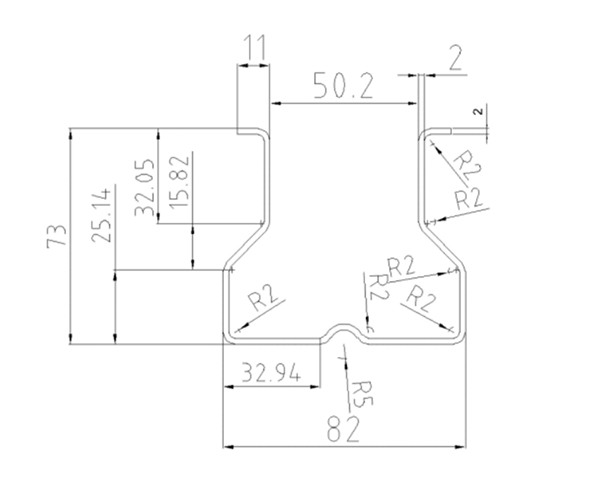

Profile:

Technical specification:

|

Warehouse Pallet Rack/Goods Shelf Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

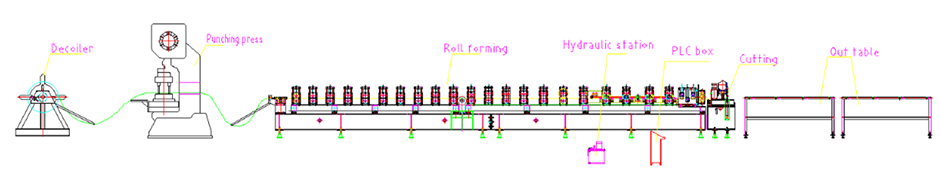

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

All we do is usually connected with our tenet " Consumer initial, Rely on 1st, devoting around the food stuff packaging and environmental safety for Quots for Automatic High Speed Ridge Cap Tile Forming Machine - Shelf Rack roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Yemen, Guatemala, Bahrain, With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers' hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Send your message to us:

-

Professional China Roof And Wall Panel Roll For...

-

OEM Customized Double Deck Metal Roofing Roll F...

-

Factory source Aluzinc Roofing Sheet Roll Formi...

-

Low price for Shelf Rack Pallet Roll Forming Ma...

-

Best Price on Roof Panel Forming Machine - C P...

-

China New Product Ceiling T Bar Roll Forming Ma...