Description

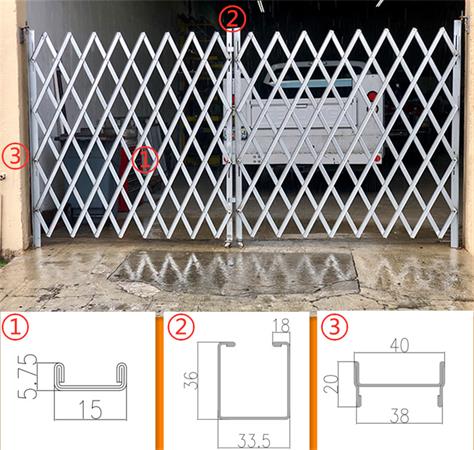

Linbay Machinery is the best scissor gate roll forming machine manufacturer. Scissor gate is also called folding gate, is often used in commercial applications to add extra security. They’re designed to secure indoor and exterior doors, windows, dock doors, entryways, corridors and hallways, while allowing light and air to circulate through the opening. Scissor security gates are ideal for schools, offices, stadiums, retail home centers, trucking terminals, factories, warehouses and many other work environments. Folding security gates are a great way to protect your inventory and your business.

Linbay Machinery offers you best roll forming machine for scissor gate. It need three roll forming machines to form it. With our roll forming machine you can produce different types of scissor gate, like portable steel scissor gate, double fixed scissor gate, single fixed scissor gate and do customization for final user.

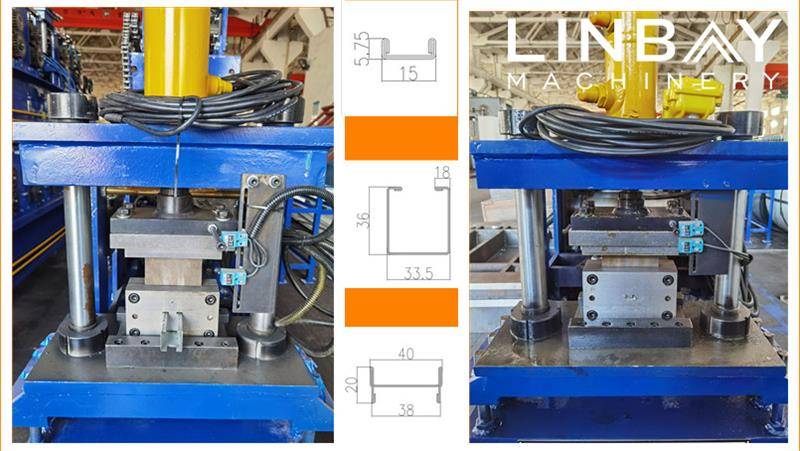

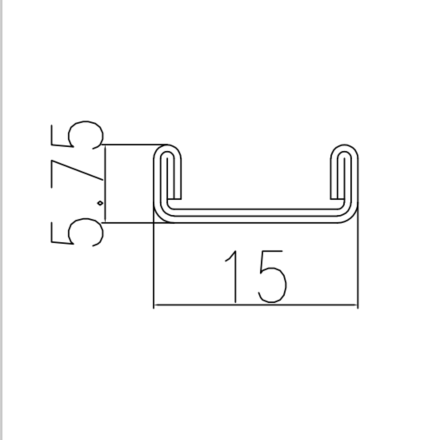

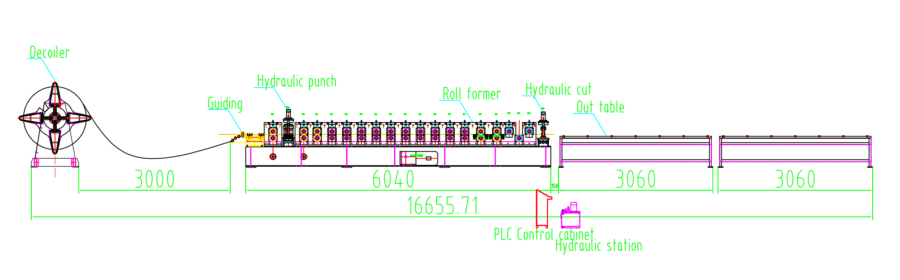

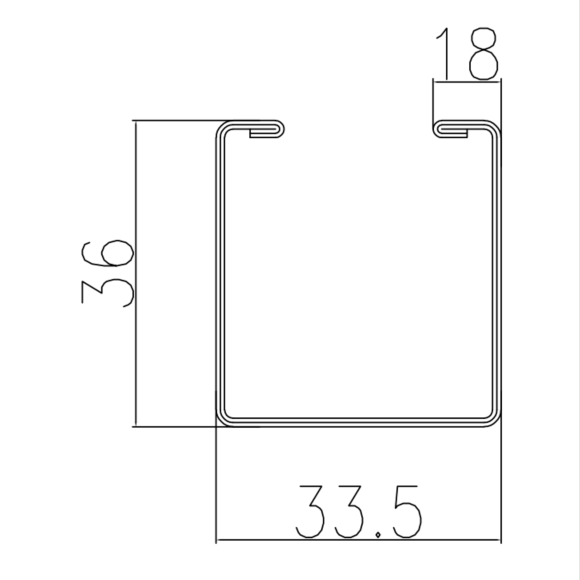

Details of Roll Forming Machine for Profile ①

| Scissor Gate U Profile Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.8-1.2 |

| C) Carbon steel | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | G250 Mpa-G350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | |

| Forming station : | 12 | 4kw |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | |

| Machine structure: | Wall panel | |

| Forming speed : | 10(M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | 45 steel, chromed | * GCr 15 |

| Cutting system : | Post-cutting | 5.5kw |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

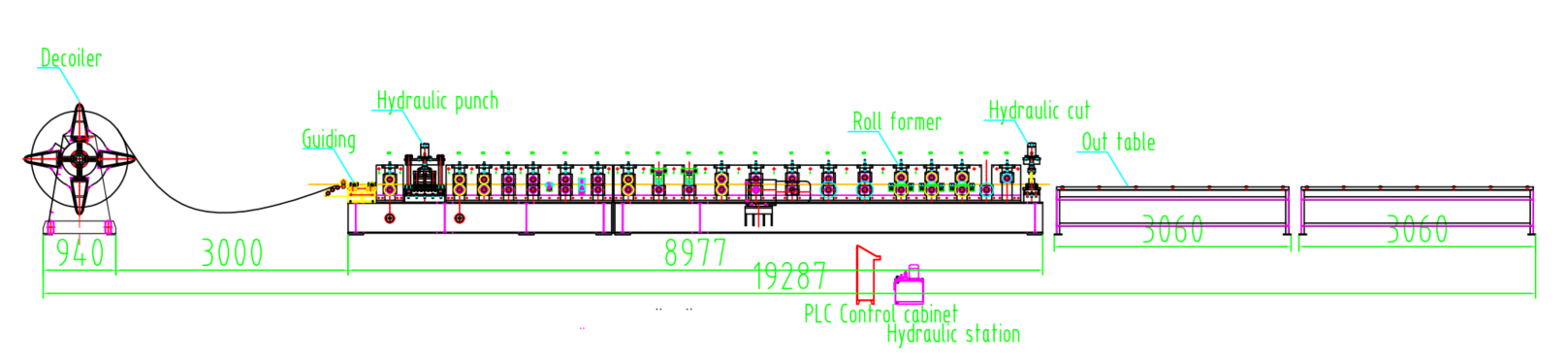

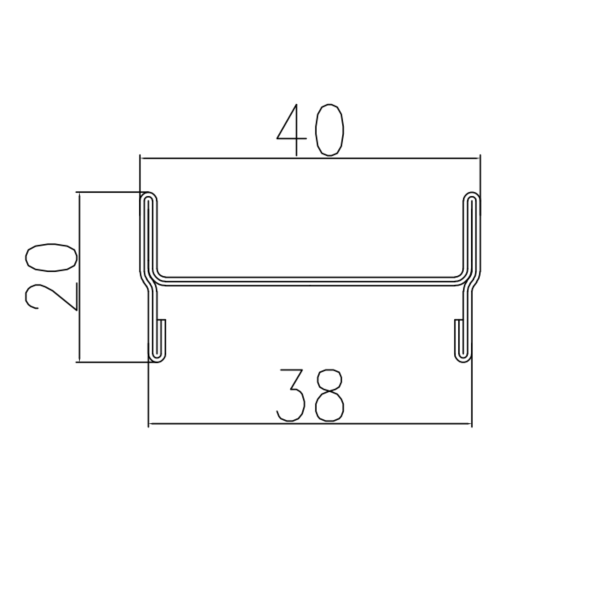

Details of Roll Forming Machine for Profile ②

| Scissor Gate C Profile Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.8-1.2 |

| C) Carbon steel | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | G250 Mpa-G350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | |

| Forming station : | 16 | 5.5kw |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | |

| Machine structure: | Wall panel | |

| Forming speed : | 10(M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | 45 steel, chromed | * GCr 15 |

| Cutting system : | Post-cutting | 5.5kw |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

Details of Roll Forming Machine for Profile ③

| Scissor Gate Profile Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.8-1.2 |

| C) Carbon steel | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | G250 Mpa-G350 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | |

| Forming station : | 14 | 5.5kw |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | |

| Machine structure: | Wall panel | |

| Forming speed : | 10(M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | 45 steel, chromed | * GCr 15 |

| Cutting system : | Post-cutting | 5.5kw |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

Q&A

1. Q: What kinds of experience do you have in producing door frame roll forming machine?

A: We have many experience in door frame machine, all of our customers are located all over the world and are very satisfied due to our excellent price-quality ratio such as Australia, USA, Ecuador, Ethiopia, Russia, India, Iran, Vietnam, Argentina, Mexico etc. Now the biggest customer we are serving is TATA STEEL INDIA, we’ve sold 8 lines on 2018, and right now we are assembling other 5 lines for them.

2. Q: What are the advantages do you have?

A: We have our own factory, we are 100% manufacturer, so we could easily control the delivery time and machine quality, offering you the best Chinese after-sales service. Besides, our innovative team is well educated with bachelor degree, who could also talk in English, realizing smooth communication when he comes to install your machine. He has more than 20 years of experience and could solve any problem alone during his work. Next, our sales team will always takes care of your every needs to make a one-to-one solution, giving you professional idea and suggestion to let you get an affordable and practical producing line. Linbay is always your best choice of roll forming machine.

3. Q: What is the delivery time of door frame roll forming machine?

A: We need to take 40-60 days from machine design to assemble it. And the delivery time should be confirmed after checking door frame drawing.

4. Q: What is the machine speed?

A: Normally line speed is around 0-15m/min, the working speed depends on your perforation drawing as well.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

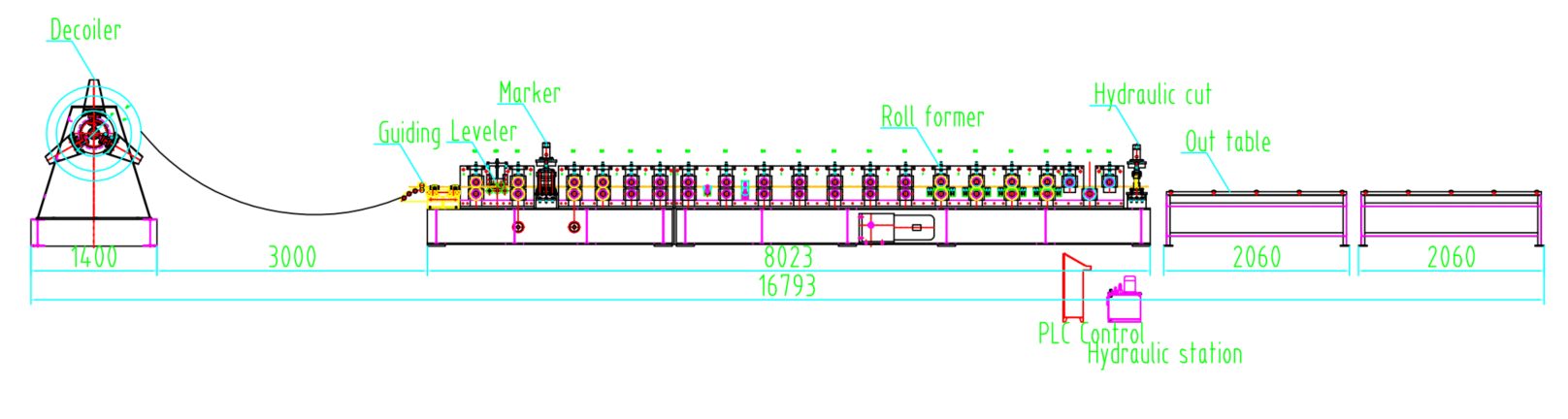

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table