Short Lead Time for Roof Tile Ridge Roll Forming Machine - Downspout Pipe roll forming machine – Linbay Machinery Detail:

Description:

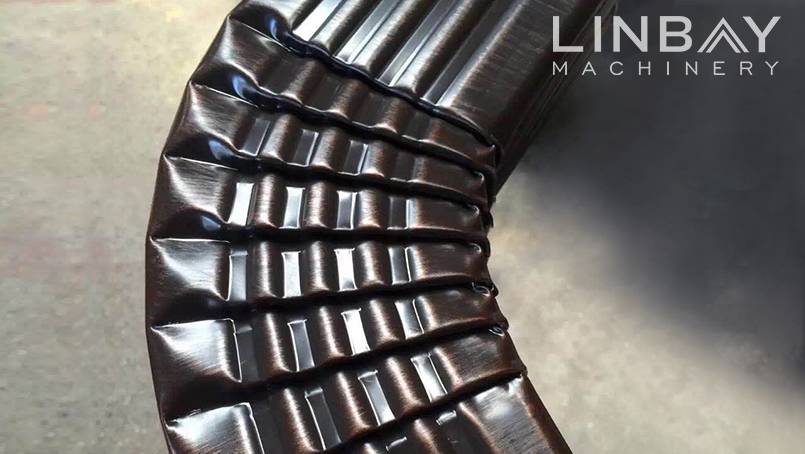

Downspout/Down Pipe Roll Forming Machine can produce the water pipes with perfect surface. It has two types: round pipe and square pipe.

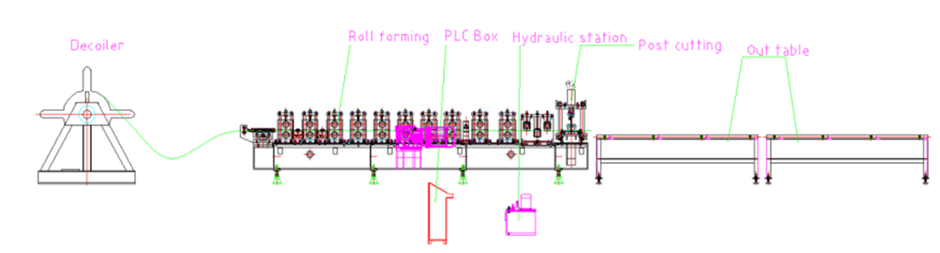

This line include Uncoiler ,Rollforming unit and cutting unit also the Pipe bender unit.

The thickness can be formed Min. 0.3mm thin and Max.2.0mm thick.

The Pipe Bender can be bent the product as 90 degree and retracted for connecting pipe ends.

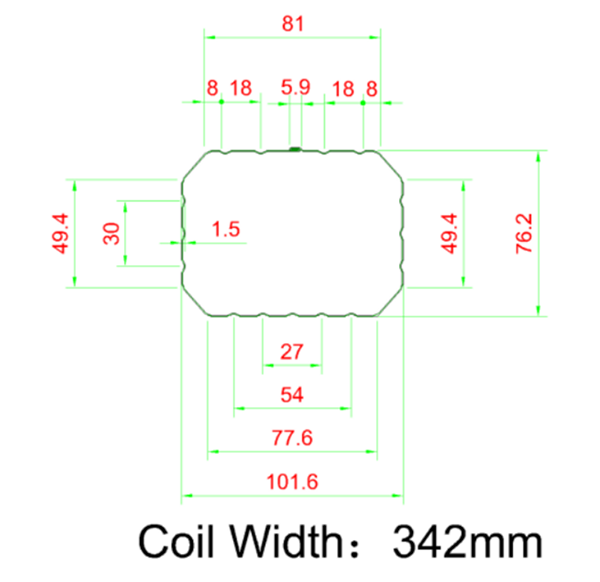

Profile:

Technical specification:

|

Downspout Pipe/Round pipe/ Square pipe roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

19 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

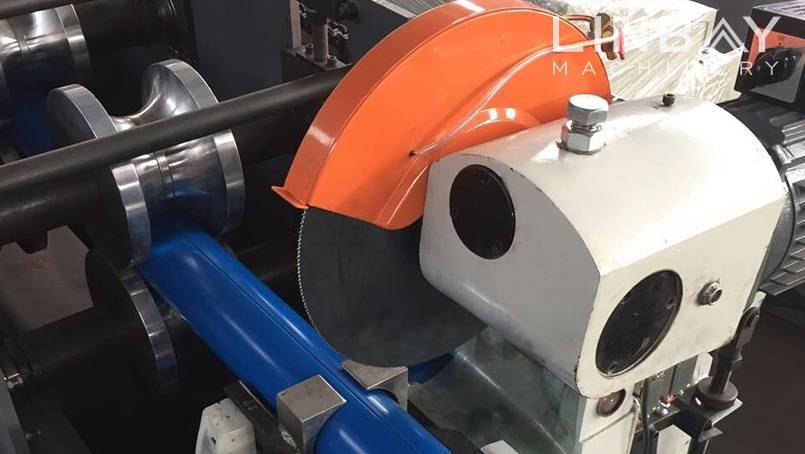

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Short Lead Time for Roof Tile Ridge Roll Forming Machine - Downspout Pipe roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: United Kingdom, Colombia, Oman, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Send your message to us:

-

Hot New Products Metal Sheet Making Machine - ...

-

Fixed Competitive Price Eletrical Rolling Machi...

-

Personlized Products Sheet Bending Roll Forming...

-

18 Years Factory Square Gutter Machine - C Z P...

-

OEM Manufacturer Steel Shutter Door Roll Formin...

-

High reputation Roof Sheet Machine - Step Beam...