We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for Well-designed 10 Years Density Plastic Polyethylene Pipes For Water, We generally offer most effective top quality merchandise and great assistance for the majority of enterprise users and traders . Warmly welcome to affix us, let’s innovate together, and fly dreams.

We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for Density Polyethylene Pipes, Plastic Pipes For Water, Rubber Pipes, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced items constantly to satisfactorily meet the needs of our clients all over the world.

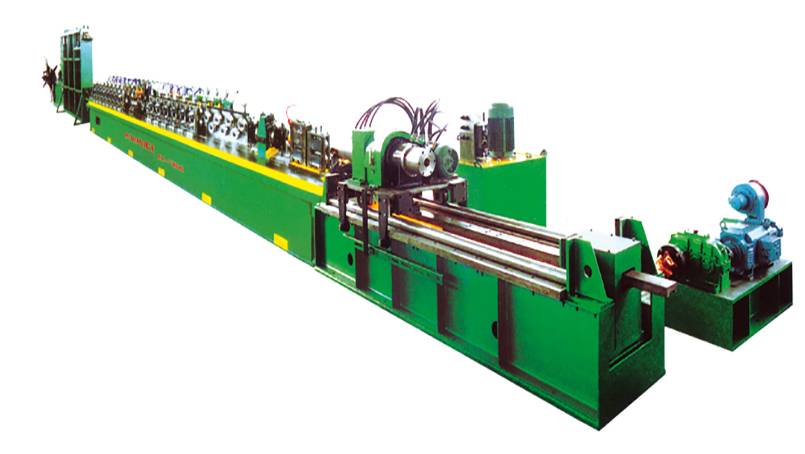

| Description | FG30 high-precision plastic composited tube mill line |

| Diameter of welded tubes | Φ13-32mm |

| Wall thickness of welded tubes | 0.4-0.8mm |

| Speed of tube welding | 10-35M/min |

| Power of major motor | 22KW |

| Power of high frequency welder | 60KW |

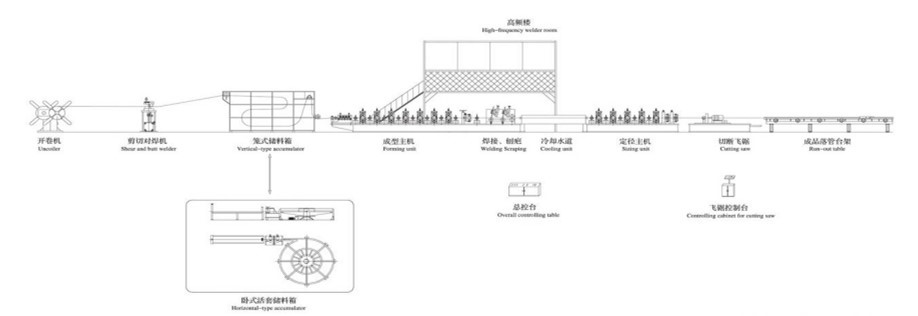

| Basic componetsUncoiler→Shearing and butt-welder→Vertical-type accumulator→Forming,welding,sizing machine→Plastic composited machine→Computer cutting saw→Run-out table | |

Description:

In order to expand our business, we cooperate with the largest welding machine company in China to produce the tube welding machine.Welcome all customers to visit the welding machine factory and make purchase with us.At present, we mainly produce high frequency carbon steel pipe welding machine, high frequency stainless steel pipe welding machine, and plastic pipe welding machine, etc. The maximum pipe diameter we can produce is 273mm. Our advantage is that our factory has the ability to produce each parts of whole line, so we can control the quality accurately and the date of delivery, each mold which has passed strict quality control standard can be sent to the hands of customers.

Flaw chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

China Supplier China Manual/Hydraulic Shelf Box...

-

Reliable Supplier China Good Steel Cut to Lengt...

-

Best-Selling Lower Cost Galvanized Steel Sheet ...

-

Professional China China Scaffolding Board Stee...

-

China Wholesale China Perfiladora De Chapa Acan...

-

New Arrival China Aerial Suspended Construction...