Wholesale OEM/ODM Steel Pipe Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

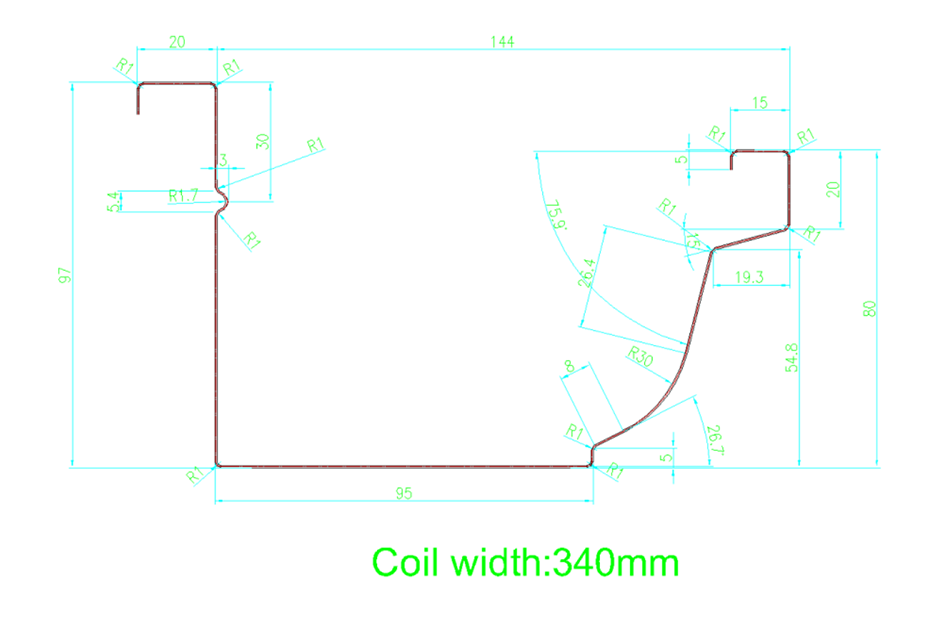

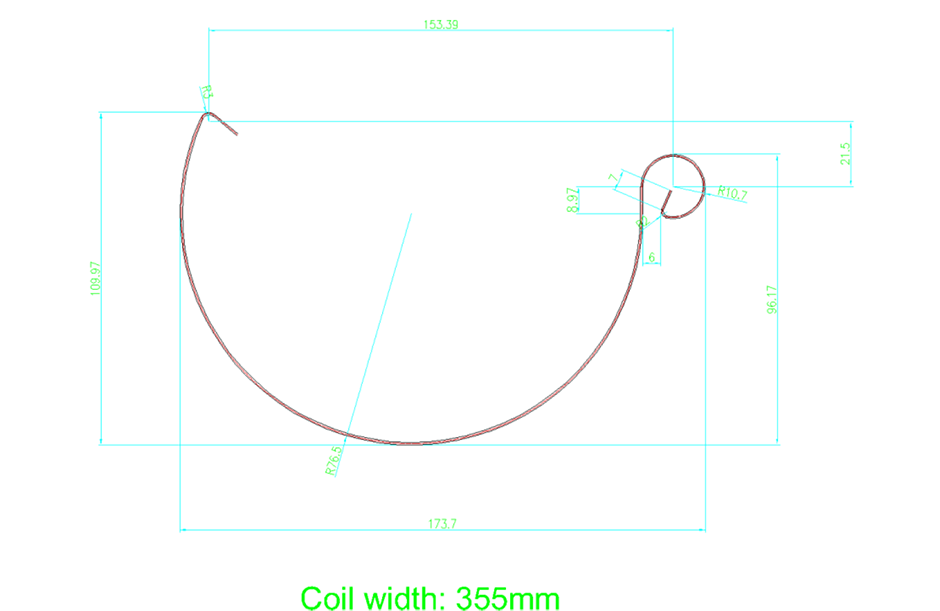

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

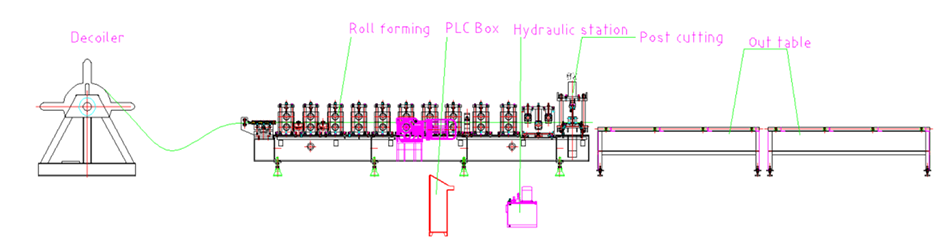

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Wholesale OEM/ODM Steel Pipe Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Angola, Qatar, Uzbekistan, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

Send your message to us:

Write your message here and send it to us

-

Factory For Used Cold Roll Forming Machine - S...

-

Factory Cheap Downspout Roll Forming Machine Ch...

-

Factory Free sample High Quality Metal Sheet Ro...

-

Good Wholesale Vendors C Z Shape Roll Forming M...

-

High definition Aluminum Cap Making Machine - ...

-

Hot-selling 240 Roll Forming Machine - Step Be...