We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Cheap PriceList for Eps/pu Sandwich Roof/wall Panel Making Machine Made In, We, with great passion and faithfulness, are prepared to present you with best companies and striding forward along with you to create a dazzling upcoming.

We attempt for excellence, support the customers”, hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Roll Forming Machine, Sandwich Steamer Machine, Solar Panel Machine, With the goal of “zero defect”. To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Description:

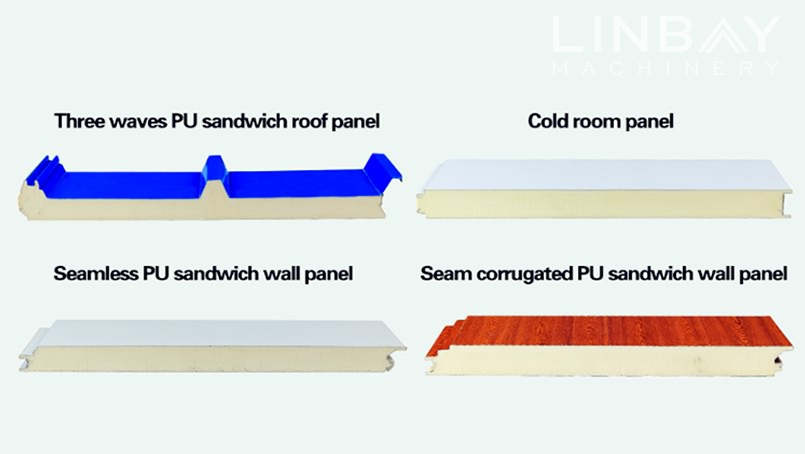

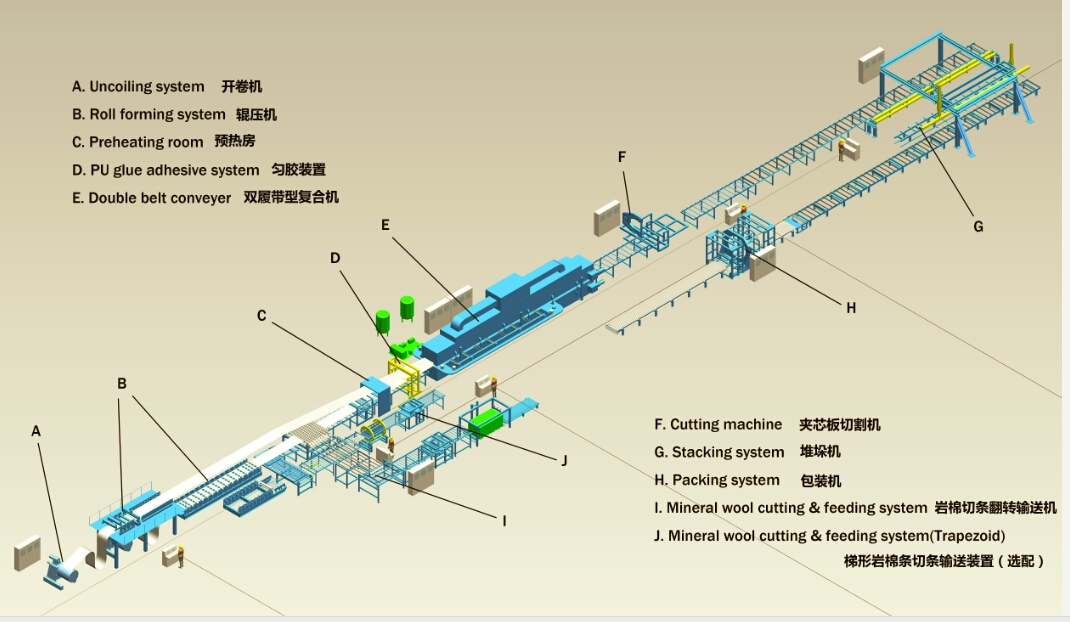

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Hot New Products China High Quality Slitting Li...

-

Discountable price Newest 20 Years Experience E...

-

Big discounting High Speed Guardrail Roll Formi...

-

100% Original Full Automatic Metal Steel Roofin...

-

100% Original Full Automatic Metal Steel Roofin...

-

China Supplier China Yufa Hydraulic Cutting Aut...