We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for High reputation Changge Gf32 Rolling Pipe Bending Machine, We are able to customize the merchandise according in your prerequisites and we will pack it in your case when you purchase.

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Bending Machine, Machine, Rolling Pipe Bending Machine, To create more creative goods, maintain high-quality products and solutions and update not only our goods but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer you and to grow stronger together. To be the real winner, starts here!

Description:

Downspout/Down Pipe Roll Forming Machine can produce the water pipes with perfect surface. It has two types: round pipe and square pipe.

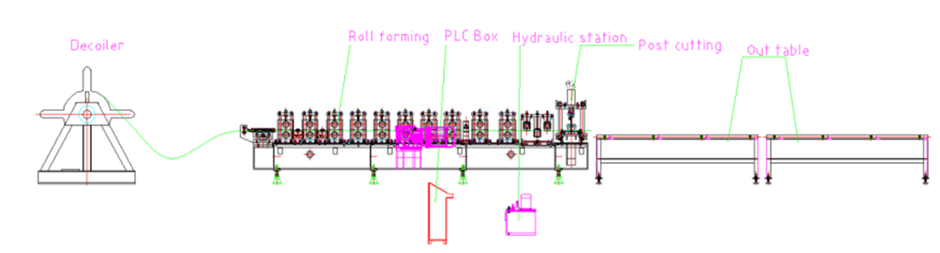

This line include Uncoiler ,Rollforming unit and cutting unit also the Pipe bender unit.

The thickness can be formed Min. 0.3mm thin and Max.2.0mm thick.

The Pipe Bender can be bent the product as 90 degree and retracted for connecting pipe ends.

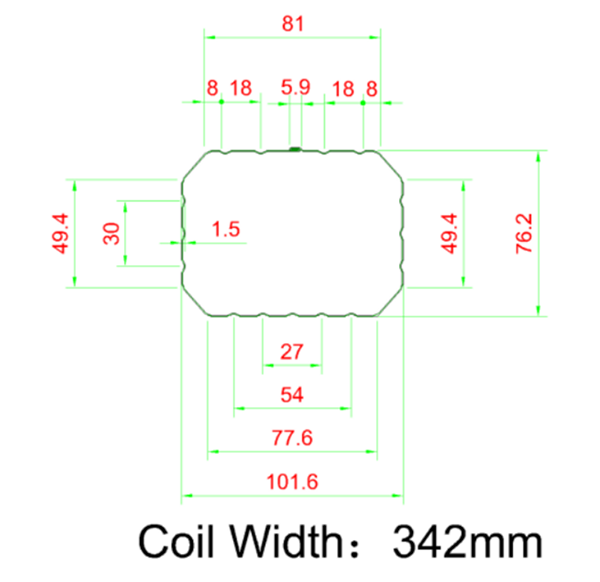

Profile:

Technical specification:

|

Downspout Pipe/Round pipe/ Square pipe roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

19 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

China Supplier China Manual/Hydraulic Shelf Box...

-

OEM Supply Color Steel Step Beam Cold Roll Form...

-

Quots for China 10-30m/Min PLC Control Storage ...

-

Super Purchasing for China Cut to Length Machine

-

Hot-selling China Aluminium Scaffolding Plank f...

-

Top Quality China Metal Roofing Roll Forming Ma...