Our firm promises all users on the first-class products and solutions along with the most satisfying post-sale assistance. We warmly welcome our regular and new buyers to join us for Factory Directly supply cz purlin roll forming machine, To deliver prospects with excellent equipment and providers, and frequently create new machine is our company’s organization objectives. We look forward for your cooperation.

Our firm promises all users on the first-class products and solutions along with the most satisfying post-sale assistance. We warmly welcome our regular and new buyers to join us for c&z purlin forming machine, Cold Roll Forming Machine, cz purlin machine, cz purlin machinery, cz purlin machines, Cz Purlin Roll Forming Machine, cz purlin roll forming machinery, cz purlin roll forming machines, Purlin Forming Machine, purlin roll former, Roll Forming Machine, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need to have a trusted supplier and value information.

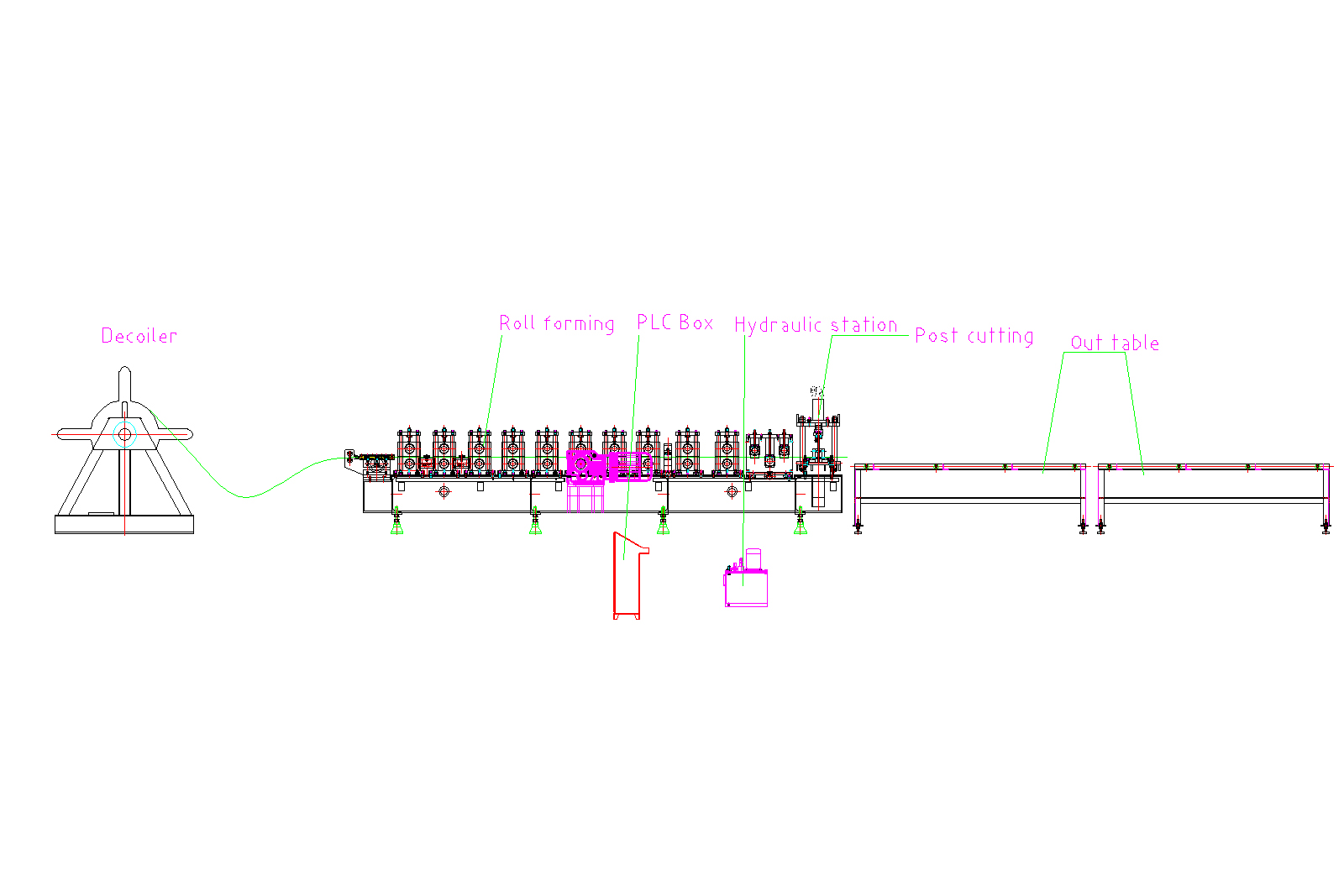

Description:

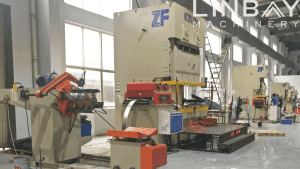

This C/Z Quick Interchangeable Roll Forming Machine adopts a special structure. The rollers for C&Z are changed very quickly without dismantle any parts . One machine can produce all specifications of C/Z/U purlins . Crimples are optional to increase rigidity of purlins. The width of the purlins can be automatically adjusted by PLC. If you need more economy then can be Handle Wheel adjusting as well. This machine we adopt Pre-cutting system.

Technical specification:

|

C/Z/U Quick Interchangeable Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Pre-cutting | Post- universal cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Factory Directly supply Chinese Market Hot Sell...

-

Quality Inspection for China Two Shapes Strut C...

-

18 Years Factory China Steel Quick-Changed C80-...

-

Wholesale Price China Metal Roof Panel Used Rol...

-

High definition China Professional High Quality...

-

Special Price for China Scaffolding Plank Walki...