High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we’re hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Top Quality China Metal Roofing Roll Forming Machine for Ibr Sheet, We’ve been glad that we’ve been steadily developing along with the active and long lasting assist of our pleased buyers!

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we’re hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for China Roll Forming Machine, metal roof machine, metal roof machines, Metal Roof Roll Forming Machine, Metal Roofing Forming Machine, metal roofing roll former, Metal Roofing Roll Forming Machine, Roll Forming, Roll Forming Machine, Roof Panel Forming Machine, Roof Roll Forming Machine, roof sheet forming machine, Roofing Machine, roofing machine manufacturers, Roofing Sheet Machine, Steel Roofing Machine, Wall Panel Roll Forming Machine, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Description

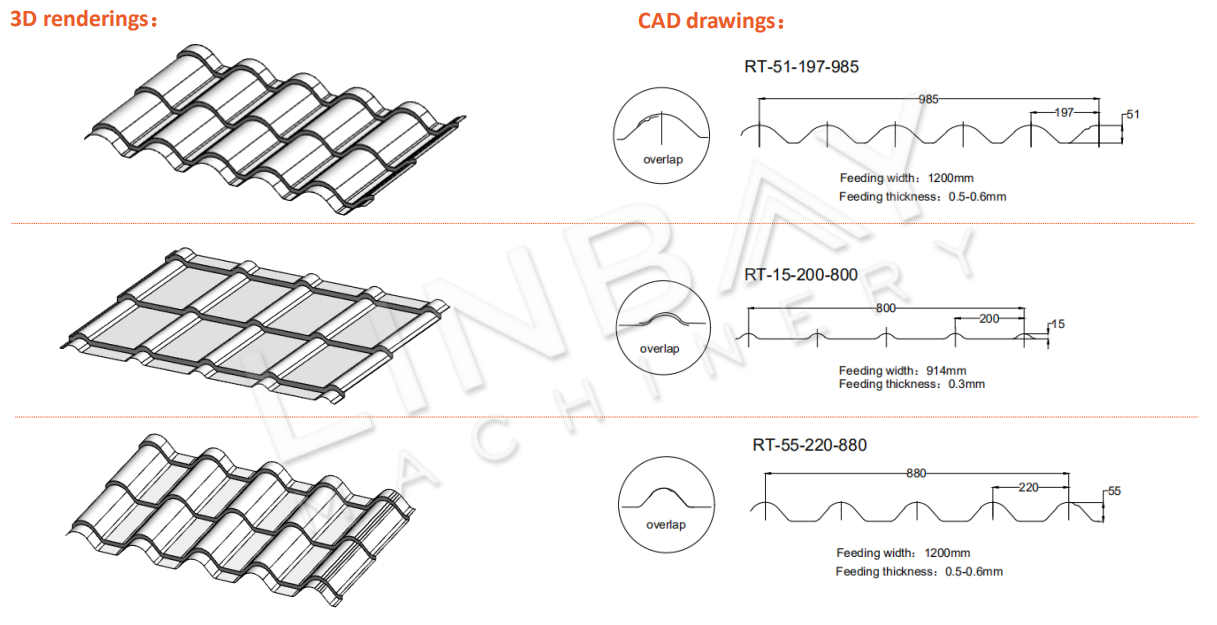

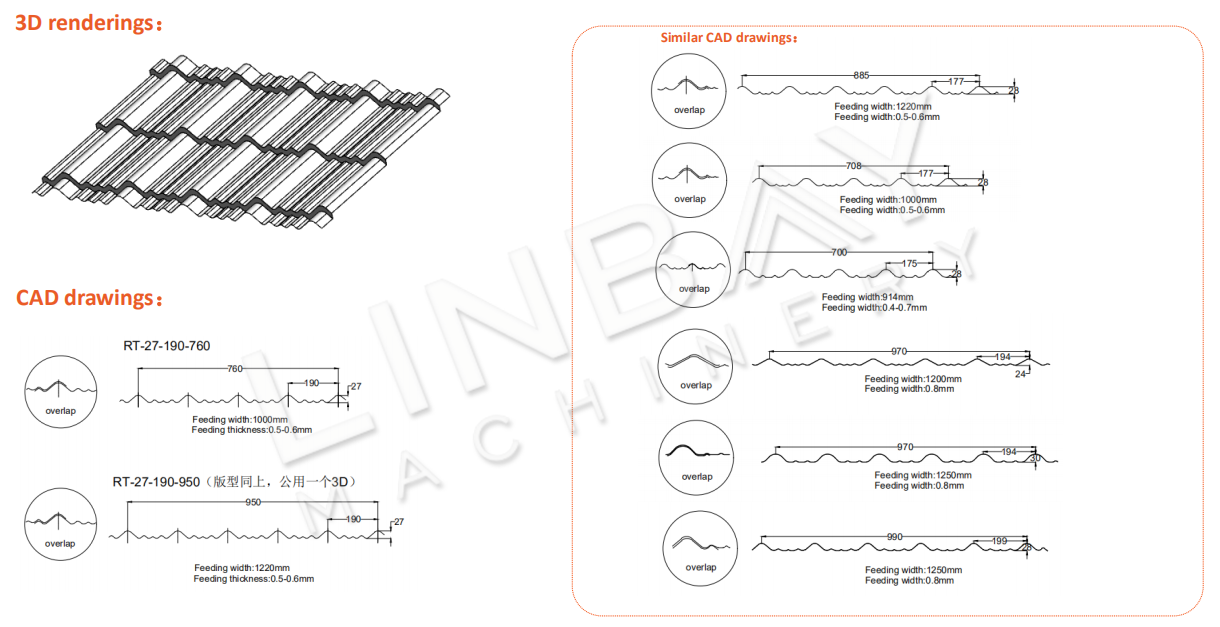

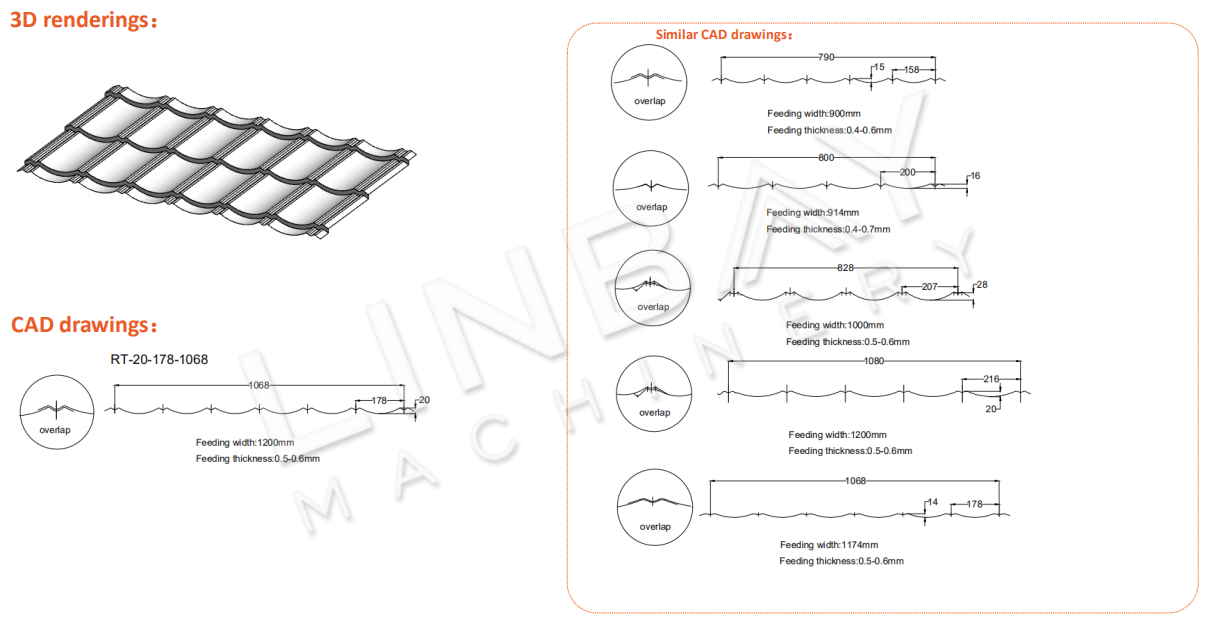

Roofing system roll forming machine has a big range of metal sheet profiles. It includes trapezoidal panel, corrugated panel, roof tile panel, metal deck panel, standing seam panel, K span panel and ridge cap. Its products are widely used in roof and wall system in workshop construction and housing construction.

The normal machinable thickness range of our roof panel roll forming machine is 0.2mm-0.8mm, the standard or more used in international market is Gauge 26 (0.45-0.5mm), working raw material is Aluminum, PPGI, Galvanized steel, Galvalume steel etc. We confirm machine’s configuration according to your drawing, specially the pitch and height of each wave. Linbay Machinery is always your best choice of roof panel roll forming machine.

Different countries has different its own commonly used profiles and name. Here are some machines more ordered by our customers:

America Latina:

①TO-725 roll forming machine

②TO-30 roll forming machine

③TO-100 roll forming machine

④TR-72 roll forming machine

⑤TR-101 roll forming machine

⑥T-101 roll forming machine (Argentine)

Indonesia:

①KR3-760 roll forming machine

②KR3-800 roll forming machine

③KR5-750S roll forming machine

④KR9-680 roll forming machine

⑤KR10-760 roll forming machine

⑥KR12-920 roll forming machine

Russia:

①C8 roll forming machine

②C21 roll forming machine

③C18 roll forming machine

UK: Box profile roll forming machine

Dubai: DSS35/200 roll forming machine

South Africa: IBR 686 roll forming machine

We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

Application

Real Case A

Description:

This roof tile roll forming machine we exported to Mexico, it use the new type of cut and press system, the new mold can make more beautiful pitch and it controls length precision within +/- 0.5mm.

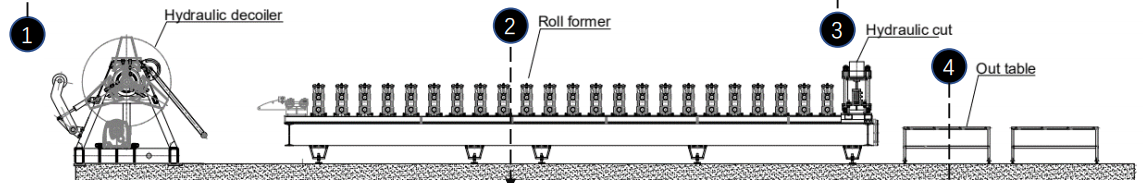

Whole Production Line of Roof Tile Roll Forming Machine

Technical Specifications

|

Roof Tile Roll Forming Machine |

||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):0.3-0.8 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 – 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | * Or according to your requirement (Optional) |

| Forming station : | 22 stands | * According to your profile drawings (Optional) |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler (Optional) |

| Punching system | No | * Hydraulic punching or punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

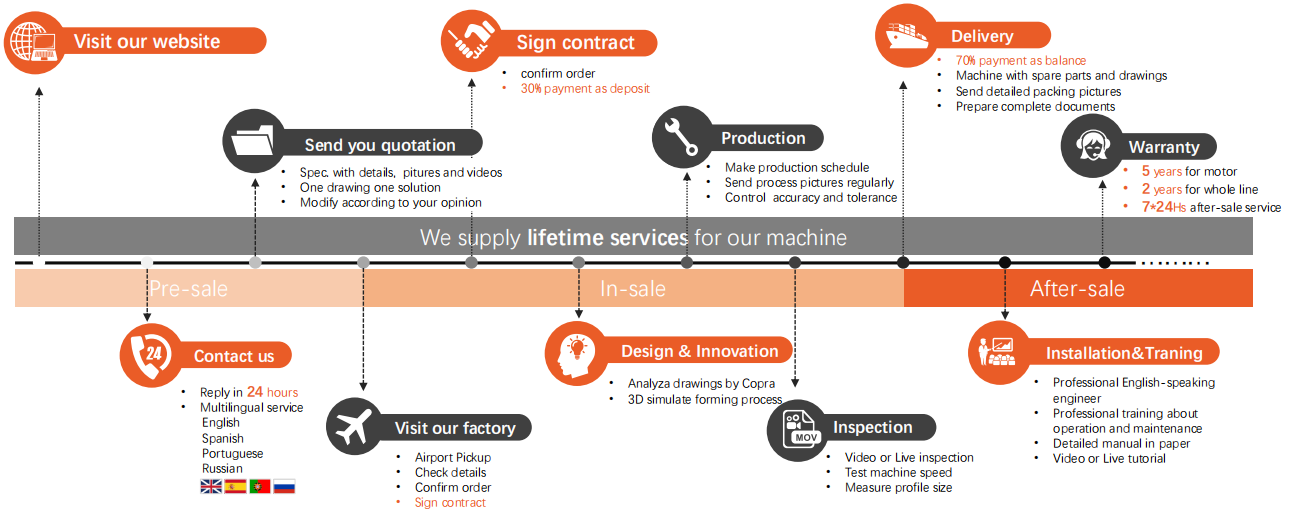

Purchase Service

Q&A

1.Q: What kinds of experience do you have in producing roof panel roll forming machine?

A: Roof/wall panel (corrugated panel) roll forming machine is the most produced machine, we have many experience of this machine. We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

2.Q: How many profiles can produce this machine?

A: According to your drawing, specially the height and pitch of each wave, if they are the same, you could produce several sizes with different feeding coil width. If you want to produce one trapezoidal panel and one corrugated panel or a roof tile, we would recommend you a double layer roll forming machine to save your space and cost of machine.

3.Q: What is delivery time of trapezoidal roof panel making machine?

A: 45 days to design from beginning to lubricate all rollers before shipment.

4.Q: What is your machine speed?

A: Our forming speed is 0-20m/min adjustable by Yaskawa frequency changer.

5.Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

2018 High quality Door Frame Rolling Shutter Ro...

-

Factory Customized China 1.5mm-2mm Galvanized S...

-

OEM/ODM Manufacturer China Supermarket Shelf St...

-

Massive Selection for China Vineyard Trellis Po...

-

Cheap price Sandwich Panel/pu Sandwich Panel Pr...

-

China Wholesale China Perfiladora De Chapa Acan...