“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for Factory Free sample China Galvanized Metal Scaffolding Plank Roll Forming Machine, Our Lab now is “National Lab of diesel engine turbo technology ” , and we own a expert R&D team and complete testing facility.

“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for Aluminum Scaffold Plank, China Scaffold Plank Board Machine, construction platform making machine, iron scaffold plank machine, scaffold board rolling machine, scaffold foot pedal machine, Scaffold plank roll forming machine, scaffolding foot plate machine, scaffolding plate making machine, Scaffolding Platform machine, Scaffolding Platform making machine, scaffolding walk plank machine, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Description

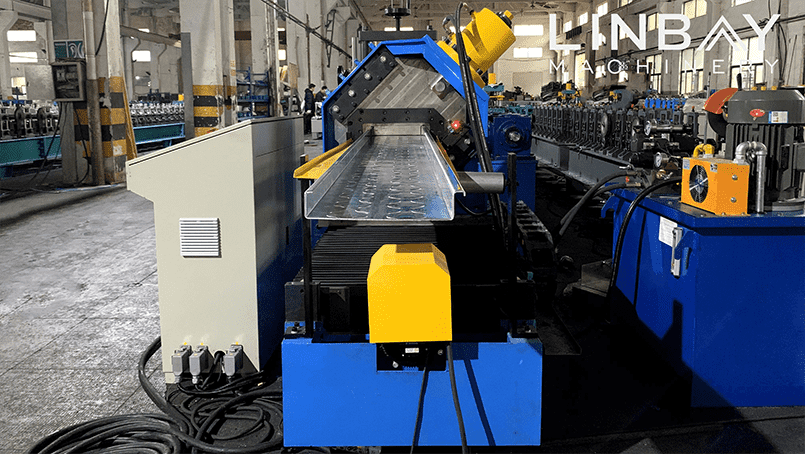

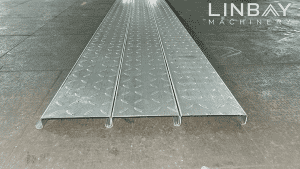

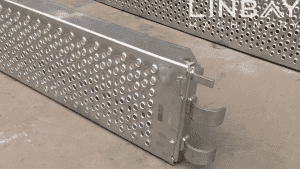

Scaffold plank roll forming machine can make scaffold plank. We adopt servo feeder to make sure the holes are in high precision. We use punching press to make line speed faster and we use hydraulic post cutting to make sure the profile perfect.

The thickness of raw material is around 1-2mm.

Application

Technical Specifications

|

Scaffold plank Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil |

|

|

|

|

Thickness(mm):1-2 |

|

|

|

|

Yield strength: 250 – 550MPa |

|

|

|

|

Tensil stress( Mpa):G350Mpa-G550Mpa |

|

|

2 |

Nominal forming speed(m/min) |

10-25 |

Or according to your requirement |

|

3 |

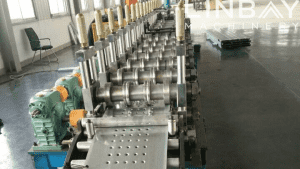

Forming station |

20 |

|

|

4 |

Decoiler |

Manual decoiler |

Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand |

Siemens |

|

6 |

PLC brand |

Panasonic |

Siemens |

|

7 |

Inverter brand |

Yaskawa |

|

|

8 |

Driving system |

Chain drive |

Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 |

GCr15 |

|

10 |

Station structure |

Torri stand structure |

Forged Iron station Or Wall panel station |

|

11 |

Punching system |

No |

Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting |

Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz |

Or according to your requirement |

|

14 |

Machine color |

Industrial blue |

Or according to your requirement |

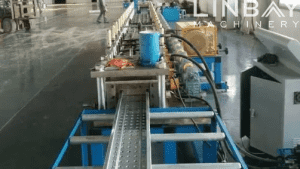

Flaw Chart

Manual decoiler–feeding–hydraulic punching station–forming machine–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Hot sale China Metal Structure C/Z/ U Purlin Ro...

-

Cheap PriceList for Eps/pu Sandwich Roof/wall P...

-

New Arrival China China Maquinas PARA Doblar Ca...

-

Cheap price China C&U 90-305mm Light Steel...

-

Massive Selection for China Vineyard Trellis Po...

-

100% Original Full Automatic Metal Steel Roofin...