To be able to ideal meet up with client’s needs, all of our operations are strictly performed in line with our motto “High High-quality, Competitive Cost, Fast Service” for Good Wholesale Vendors Automatic Big Type Roller Shutter Door Forming Machine, Are you still looking for a quality product that is in accordance with your good company image while expanding your product range? Try our quality products. Your choice will prove to be intelligent!

To be able to ideal meet up with client’s needs, all of our operations are strictly performed in line with our motto “High High-quality, Competitive Cost, Fast Service” for metal shutter door machine, PU shuttter door machine, Roll Forming Machine, rolling shuter machine price, Rolling Shutter Door Machine, Rolling Shutter Machine, rolling shutter machine manufacturer, Shutter Door Machine, shutter slat roll former, slat roller door machine, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

Description:

Roller Shutter Door Roll Forming Machine produce stainless steel rolling shutter doors and color steel rolling shutter doors. We use punching press to make different hollow-carved designs. If you ask, we can also produce PU Rolling Shutter Door Roll Forming Machine, which machine can make fire resistance and thermal insulation rolling shutter doors.

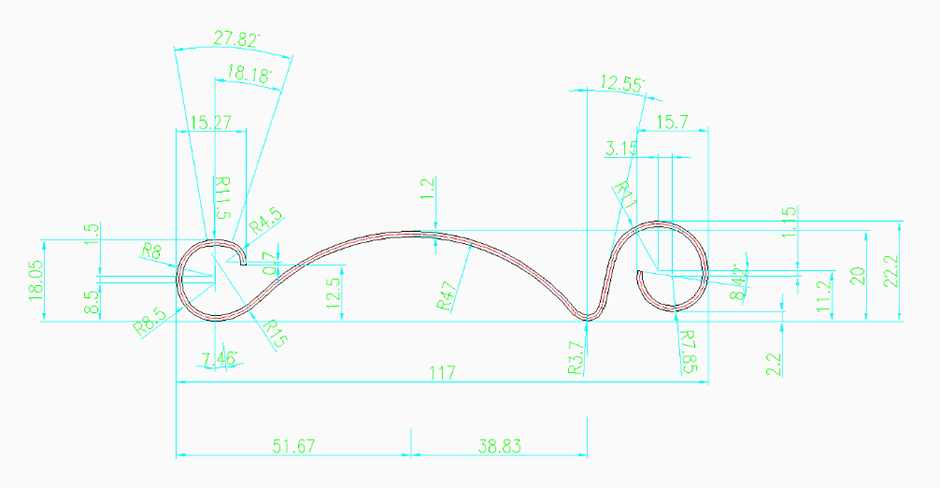

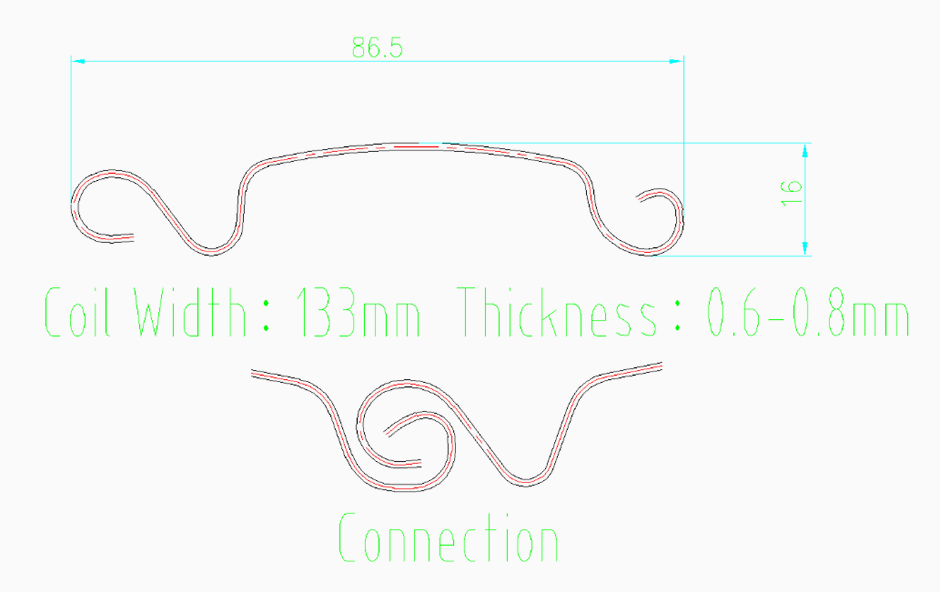

Profile:

Technical specification:

|

Roller Shutter Door roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.0-2.0 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

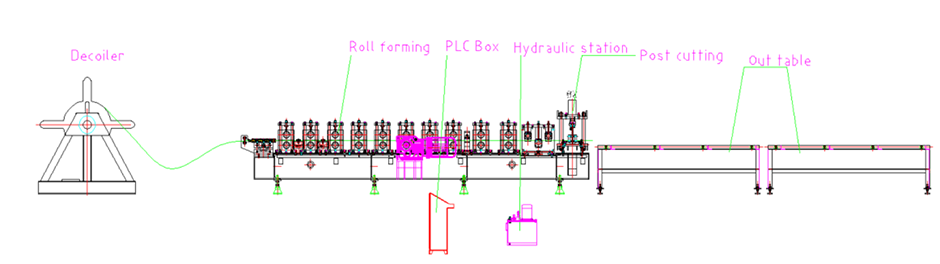

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Hot Selling for China Automatic Gutter Downspou...

-

High reputation Changge Gf32 Rolling Pipe Bendi...

-

Wholesale Price China Metal Roof Panel Used Rol...

-

OEM Supply Color Steel Step Beam Cold Roll Form...

-

High Quality China Two-Year Warranty Shelf Load...

-

Cheap PriceList for Eps/pu Sandwich Roof/wall P...