Iphrofayela

I-Metal fence post iwuhlobo lokubiya oluvame ukusetshenziswa eYurophu, olufana nensika yocingo lwamapulangwe. Yakhiwe ngensimbi engu-0.4-0.5mm ehlanganiswe ngombala noma insimbi, enikeza ukwenziwa ngokwezifiso okuphezulu komumo nombala. Imiphetho yocingo ingasikwa ibe yizimo ezisaqanda noma igcinwe iqondile.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

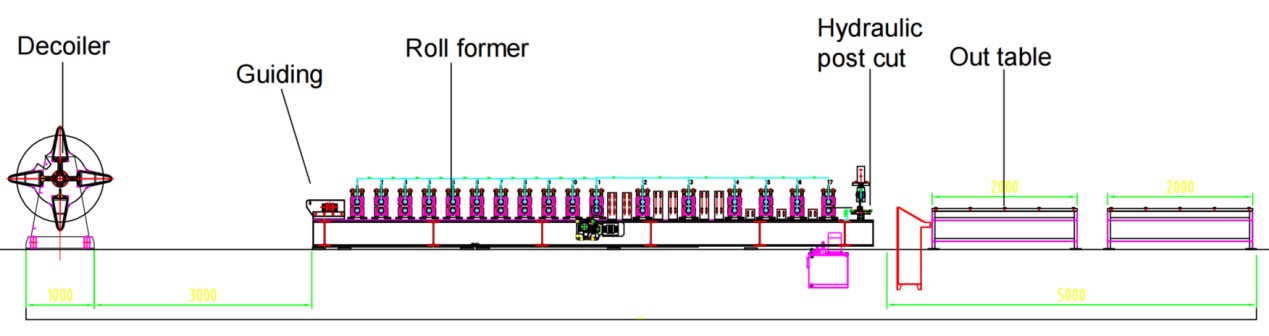

Ishadi eligelezayo: I-Decoiler--Guiding--Roll forming machine-Hydraulic cut-out table

1.Isivinini somugqa:0-12 m/min, siyalungiseka

2.Impahla efanelekile:Insimbi enama-galvanized, insimbi ependwe ngaphambilini

3.Material ukujiya: 0.4-0.5mm

I-4.Umshini wokwenza i-Roll: Isakhiwo sephaneli yodonga kanye nesistimu yokushayela iketango

I-5.Isistimu yokusika: Yeka ukusika ngemva komshini wokwenza umqulu, gingqa izitobhi zangaphambili lapho usika.

6.PLC iKhabhinethi: Siemens uhlelo.

Imishini

1.I-Decoiler*1

2.Umshini wokwenza umqulu*1

3.Umshini wokusika amanzi*1

4.Ithebula elingaphandle*2

5.PLC control cabinet*1

6.Isiteshi samanzi*1

7.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Ikesi langempela-Incazelo

I-Decoiler

Idivayisi yokunweba eyinhloko ku-uncoiler ivumela ukulungiswa kwedayamitha yangaphakathi ukuze ifake amakhoyili ensimbi anobubanzi bangaphakathi obusuka ku-460-520mm. Ukwengeza, i-uncoiler ifakwe izici ezimbili zokuphepha: ingalo yokucindezela kanye ne-coil retainer yangaphandle. Ngesikhathi sokushintsha ikhoyili, ingalo yokunyathelisa ivikela ikhoyili yensimbi ukuyivimbela ukuthi ingaqhumi futhi ibangele ukulimala kubasebenzi. I-coil retainer yangaphandle ivimbela ikhoyili yensimbi ukuthi ingasheleli futhi iwe ngenkathi iqaqa.

Ukuqondisa

Amarola aqondisayo azoqondisa ngempumelelo ikhoyili yensimbi kumarola akhayo, aqinisekise ukuhleleka okunembile phakathi kwekhoyili nomshini wokwenza ama roll, ngaleyo ndlela kuncishiswe ingozi yokugoba noma ukuchezuka.

Umshini wokwenza ama-roll

Umshini wokwenza ama-roll uyingxenye ebalulekile yawo wonke umugqa wokukhiqiza. Lo mshini unesakhiwo sephaneli yodonga lwesiteshi esakhayo, esinamarola akha aqhutshwa ngamaketango. Ipali yocingo iqiniswa ngezimbambo eziningi ukuze ithuthukise amandla ayo namandla okuvikela. Ukwengeza, ukugoqa komphetho ezinhlangothini zombili zokuthunyelwe kuqedwa emshinini wokwenza umqulu ukuze kuncishiswe ukucijile nokunciphisa ubungozi bokuklwebheka.

Ama-roller akhayo enziwe ngezinto ze-Gcr15, insimbi enekhabhoni ephezulu ye-chromium eyaziwa ngobulukhuni bayo obuhle kakhulu nokumelana nokugqoka. Amarola nawo ane-chrome-plated ukuze andise impilo yawo. Amashafu enziwe ngezinto ezingu-40Cr futhi aphathwa ngokushisa ukuze aqine.

Ukusika kweHydraulic

Umshini wokusika kulo mugqa wokukhiqiza unesisekelo esinqunyiwe, okwenza ikhoyili yensimbi iyeke ukuya phambili ngesikhathi sokusika. Uma ufuna ukukhulisa isivinini sokukhiqiza, sinikeza umshini wokusika endizayo. Ekucushweni kwe-"Flying", isisekelo somshini wokusika singaqhubekela phambili futhi sibuyele emuva kuthrekhi ngesivinini esifanayo nomshini wokwenza. Lo mklamo uvumela ukuthuthukiswa okuqhubekayo kwekhoyili yensimbi ngomshini wokwenza, ukususa isidingo sokumisa ukusebenza ngesikhathi sokusika futhi ngaleyo ndlela kuthuthukiswe isivinini esiphelele somugqa wokukhiqiza.

Isiteshi samanzi

Isiteshi sethu se-hydraulic sifakwe abalandeli bokupholisa ukuze basuse ukushisa ngendlela efanele, ukuqinisekisa ukusebenza okuqhubekayo kanye nokuthuthukisa umkhiqizo. Ngezinga eliphansi lokuhluleka kanye nokuqina okuhlala isikhathi eside, isiteshi sethu se-hydraulic siletha ukusebenza okuthembekile.

Ikhabhinethi yokulawula ye-PLC ne-Encoder

Isifaki khodi siguqula ubude obuzwiwayo bekhoyili yensimbi bube amasignali kagesi adluliselwa kukhabhinethi yokulawula ye-PLC. Ngaphakathi kwekhabhinethi yokulawula, imingcele efana nesivinini sokukhiqiza, umkhiqizo ngamunye wokukhiqiza, nobude bokusika kungalawulwa. Ngokulinganisa okunembile kanye nempendulo evela kusifaki khodi, umshini wokusika ungagcina ukunemba kokusika ngaphakathi kwe-±1mm.

Misa ukuze usike i-VS Engami ukuze usike

Enqubweni yokusika, kunezinketho ezimbili ezitholakalayo:

Isixazululo sokusika esilungisiwe (Yeka ukusika):Isisekelo somshini wokwenza i-cutter kanye ne-roll sixhunywe ngokuqinile. Ngesikhathi sokusika, ikhoyili yensimbi iyayeka ukuya kumqulu wangaphambili. Ngemva kokusika, ikhoyili yensimbi iqala kabusha ukuya phambili.

Isixazululo sokusika endizayo (Ukungami ukuze usike):Umshini wokusika uhamba ngokulandelana kumathrekhi esisekelweni somshini, ugcina ukuthula okuhlobene nendawo yokusika. Lokhu kuvumela ikhoyili yensimbi ukuthi iqhubeke futhi ikhiqize.

Isifinyezo kanye nezincomo:

Isixazululo endizayo sinikeza okukhiphayo okuphezulu kanye nesivinini sokukhiqiza uma kuqhathaniswa nesixazululo esimisiwe. Amaklayenti angakhetha ngokusekelwe ezidingweni zawo zamandla okukhiqiza, isabelomali nezinhlelo zokuthuthukisa. Ukuvumela isabelomali, ukukhetha isixazululo esindizayo kunganciphisa izinkinga zokuthuthukiswa komugqa wesikhathi esizayo futhi kususe umehluko wezindleko ngemva kokuthola umkhiqizo ophezulu.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle