Perfil

Rolling shutter slats are a crucial component of rolling shutters, with different design profiles preferred in various regional markets. Cold roll forming lines are a common and efficient choice for producing these slats.

The Linbay Team can provide suitable production solutions based on our experience, the production requirements for each profile, and the punching needs.

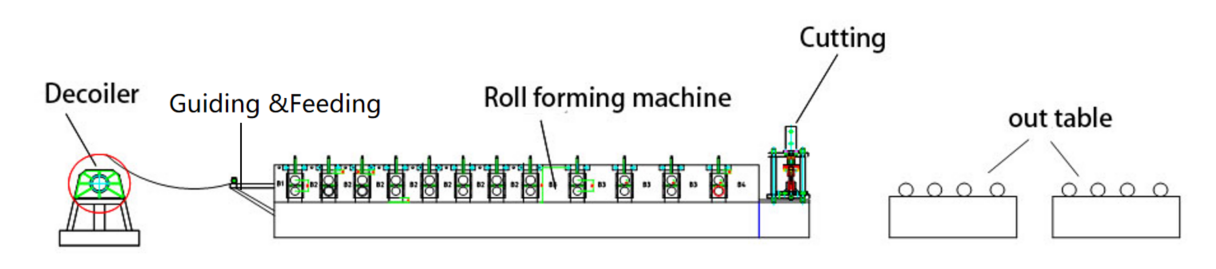

Real case-Flow chart

Hydraulic decoiler--Guiding--Roll forming machine--Hydraulic cutting machine--Out table

Real case-Main Technical Parameters

1.Line speed: 0-12m/min, adjustable

2.Suitable material:Galvanized steel

3.Material thickness: 0.6-0.8mm

4.Roll forming machine: Cast-iron structure

5.Driving system: Chain driving system

6.Cutting system: Hydraulic power. Stop to cut, roll former needs to stop when cutting.

7.PLC cabinet: Siemens system.

Real case-Machinery

1.Manual decoiler*1

2.Roll forming machine*1

3.Hydraulic cutting machine*1(Each rolling shutter slat profile require 1 separate cutting blade)

4.Out table*2

5.PLC control cabinet*1

6.Hydraulic station*1

7.Spare parts box(Free)*1

Real case-Description

Decoiler

● Roller shutter slats: Due to their smaller thickness and width, manual and motorized decoilers are sufficient to meet uncoiling requirements.

● Manual version: Non-powered, relying on the force of the forming rollers to pull the steel coil forward. It has low uncoiling efficiency and slightly lower safety. Mandrel expansion is done manually. It is cost-effective but not suitable for large-scale continuous production.

●Motor version: Powered by a motor, it increases uncoiling efficiency and reduces the need for manual intervention, saving labor costs.

Optional Decoiler Type: Double-Head Decoiler

● Versatile widths: A double-head decoiler can store steel coils of different widths, suitable for double-row forming machines.

● Continuous operation: While one head is uncoiling, the other can be loading and preparing a new coil. When one coil is used up, the decoiler can rotate 180 degrees to

Guiding

● Primary function: To align the steel coil with the machine's centerline, preventing misalignment that can cause twisting, bending, burrs, and dimensional issues in the finished product.

● Guiding devices: Multiple guiding devices at the feed inlet and within the roll forming machine enhance the guiding effect.

● Maintenance: Regularly calibrate the distance of the guiding devices, especially after transport and during long-term use.

● Pre-shipment: The Linbay team measures and records the guiding width in the user manual for customer calibration upon receipt.

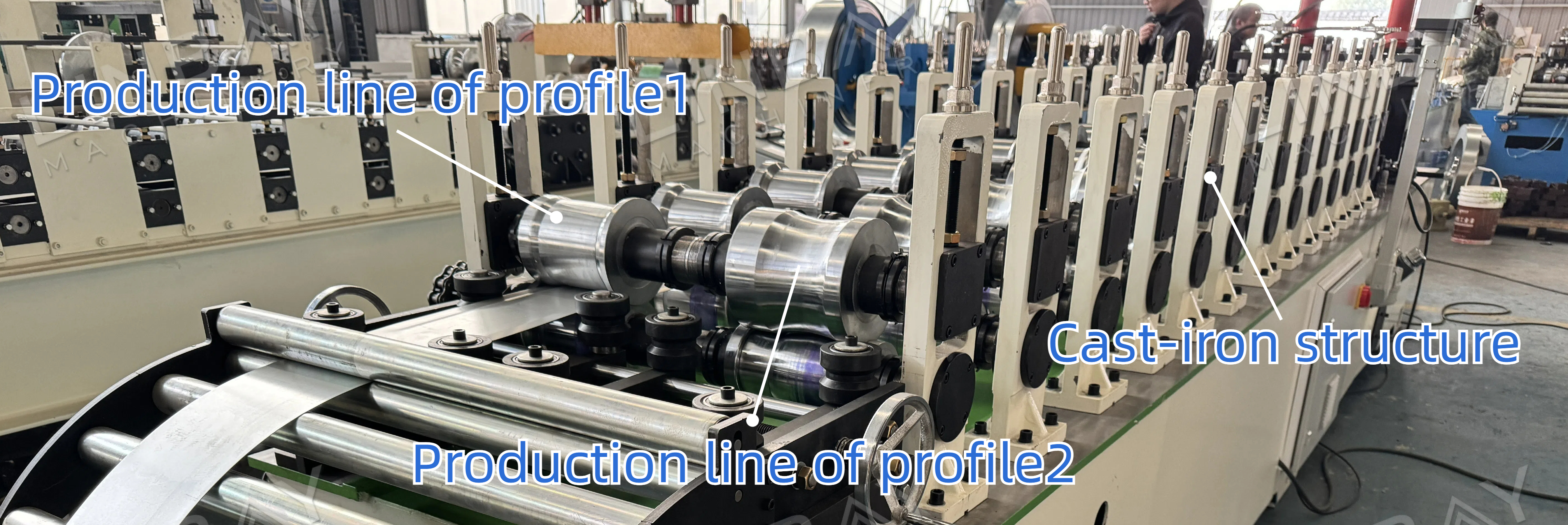

Roll forming machine

● Versatile shapes: The double-row structure can handle rolling shutter slats of two different shapes, reducing machine and space costs for clients.

● Note: The two production lines cannot run simultaneously. For high production demands of both profiles, it is recommended to use two separate production lines.

● Structure: Features a cast-iron stand and chain drive system.

● Chain cover: The chains are protected by a metal mesh, ensuring worker safety and preventing debris from damaging the chains.

● Rollers: Chrome-plated and heat-treated for rust and corrosion resistance, extending their lifespan.

● Main motor: Standard 380V, 50Hz, 3-phase, with customization available.

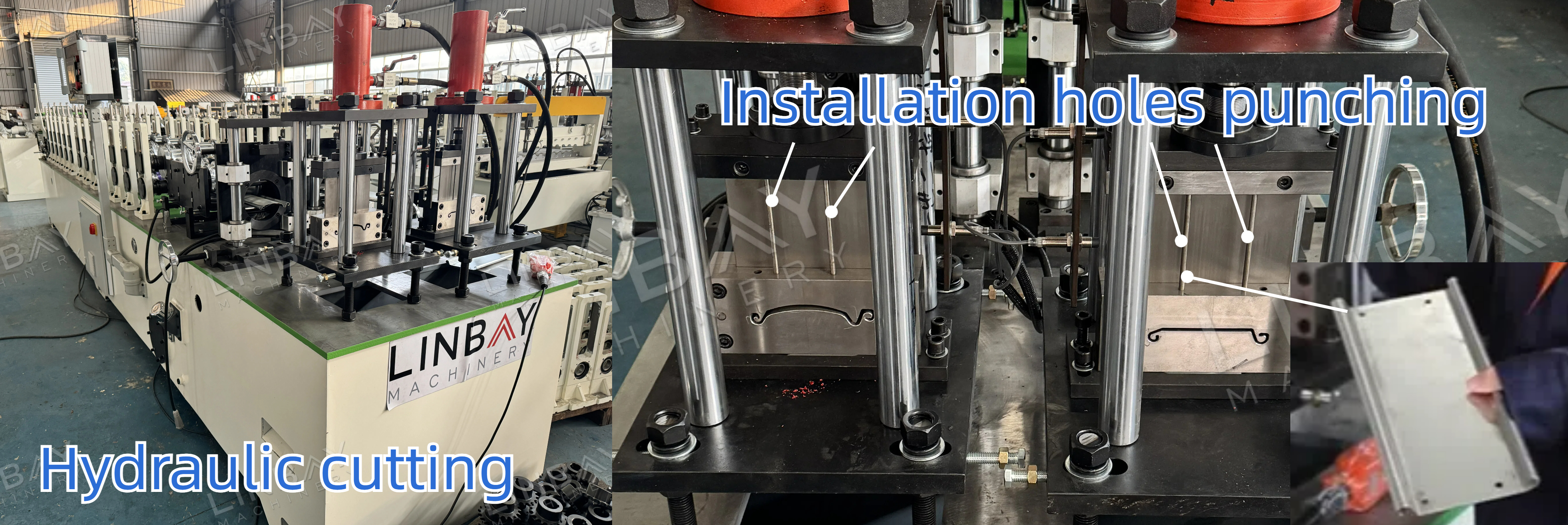

Hydraulic cutting machine

● Precision-engineered blades: Designed to match the rolling shutter slat specifications, ensuring smooth, deformation-free, and burr-free cutting edges.

● High cutting length accuracy: Tolerance within ±1mm, achieved using an encoder to measure the steel coil's advance length, converting it to electrical signals, and feeding this data back to the PLC cabinet. Workers can set the cutting length, production quantity, and speed on the PLC screen.

Optional device: Installation holes punching

● End holes: Each end of the rolling shutter slats has two holes matching the mounting fasteners. These holes can also be made on the forming line, reducing manual drilling time and costs.

● Punching and cutting: Two punches are located before and after the cutting blades, sharing a single hydraulic station to enable simultaneous cutting and punching.

● Customizable punching: Hole size and distance from the edge can be customized.

Optional device: Standalone hydraulic punch machine

● Suitable for continuous or dense punching: Ideal for high-frequency punching needs.

● Efficient production coordination: When the demand for punched rolling shutters is lower than for non-punched shutters, separating the punching and forming processes into two independent production lines can enhance overall efficiency.

● Custom punching dies: If the customer has new punching die styles after receipt, we can customize new dies within the original hydraulic punch machine's feed width range.

Testing

● Our engineers will calibrate each stage of the double-row machine before shipment to ensure that production can start promptly upon receipt.

● The produced rolling shutters will be compared 1:1 with the drawings.

● We will also cut approximately 2 meters of profile and assemble 3-4 pieces to test that the shutters fit tightly without loosening and roll up with the appropriate gap.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table