Profile

Metal fence is a popular choice for fencing in Europe, resembling traditional wooden plank fencing. Crafted from 0.4-0.5mm color-coated steel or galvanized steel, it provides durability and aesthetic appeal. The fence's end edges can be customized with oval or straight cuts.

Real case-Main Technical Parameters

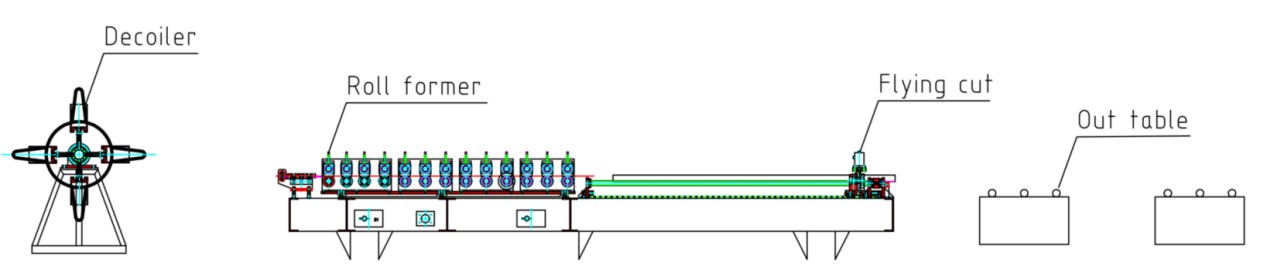

Flow chart: Decoiler--Guiding--Roll forming machine--Flying hydraulic cut--out table

1.Line speed: 0-20m/min, adjustable

2.Suitable material:Galvanized steel, pre-painted steel

3.Material thickness: 0.4-0.5mm

4.Roll forming machine: Wall-panel structure and chain driving system

5.Cutting system: Flying cutting after roll forming machine, roll former doesn’t stop when cutting.

6.PLC cabinet: Siemens system.

Real case-Machinery

1.Decoiler*1

2.Roll forming machine*1

3.Flying hydraulic cutting machine*1

4.Out table*2

5.PLC control cabinet*1

6.Hydraulic station*1

7.Spare parts box(Free)*1

Real case-Description

Decoiler

The decoiler is equipped with two safety devices: the press arm and the outward coil retainer. During the coil replacement process, the press arm secures the steel coil, preventing it from springing up and causing injury to workers. The outward coil retainer prevents the coil from sliding and falling off during unwinding.

Guiding

The guiding rollers ensure alignment between the steel coil and the roll forming machine's centerline, preventing distortion during the forming process. Before shipment, we measure and document the distances of the guiding rollers, providing our clients with detailed instructions for timely machine adjustment upon receipt.

Roll forming machine

The roll forming machine is the pivotal component of the entire production line. This machine utilizes a wall panel structure for the forming station. The rotation of the forming rollers is driven by a chain mechanism.

The fence post features multiple reinforcing ribs, enhancing its strength and protective capabilities. Additionally, the edge folding process on both sides of the post is completed on the roll forming machine, reducing sharpness and minimizing the risk of scratches.

The material of the forming rollers is Gcr15, a high-carbon chromium bearing steel known for its excellent hardness and wear resistance. The rollers are chrome-plated to prolong their lifespan. The shafts are made of 40Cr material and undergo heat treatment.

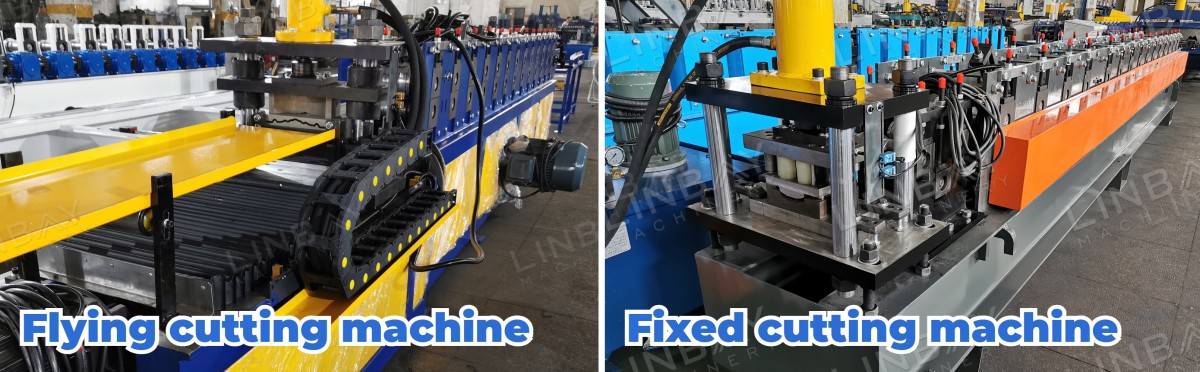

Flying hydraulic cut

In this production line, we utilize a flying cutting machine, which can move forward and backward to match the forming speed, enabling continuous passage of steel coils through the forming machine and shear.

If your production speed requirements fall within the 0-12m/min range, a fixed cutting machine would be more suitable. In the "Fixed" solution, the cutting machine requires the steel coil to stop moving forward during cutting, resulting in a slightly slower overall line speed compared to the "Flying" solution.

Hydraulic station

Our hydraulic station is equipped with cooling fans, which efficiently dissipate heat to ensure continuous operation and enhance productivity. The hydraulic station boasts a low failure rate and long-lasting durability.

PLC control cabinet & Encoder

The encoder converts the sensed length of the steel coil into electrical signals transmitted to the PLC control cabinet. Within the control cabinet, parameters such as production speed, individual production output, and cutting length can be controlled. With precise measurement and feedback from the encoder, the cutting machine can maintain cutting accuracy within ±1mm.

Stop to cut VS Non-stop to cut

In the cutting process, there are two options available:

Fixed cutting solution (Stop to cut): The cutter and roll forming machine base are fixedly connected. During cutting, the steel coil stops moving into the roll former. After cutting off, the steel coil resumes its forward motion.

Flying cutting solution (Non-stop to cut): The cutting machine moves linearly along tracks on the machine base, maintaining relative stillness with the cutting point. This allows the steel coil to continuously advance and produce.

Summary and recommendation:

The flying solution offers higher output and production speed compared to the fixed solution. Clients can choose based on their production capacity needs and development plans. The budget permitting, opting for the flying solution can reduce future line upgrade hassles and offset the cost difference after getting higher output.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table